Are you looking for an essay on ‘Hydro-Electric Plants’? Find paragraphs, long and short essays on ‘Hydro-Electric Plants’ especially written for school and college students.

Essay on Hydro-Electric Plants

Essay Contents:

- Essay on Introduction to Hydro-Electric Plants

- Essay on the Selection of Site for a Hydro-Electric Plants

- Essay on the Elements of Hydro-Electric Plants

- Essay on the Classification of Hydro-Electric Plants

- Essay on the Advantages and Disadvantages of Hydro-Electric Plants

- Essay on the Application of Hydro-Electric Plants

Essay # 1. Introduction to Hydro-Electric Plant:

In hydro-electric plants energy of water is utilised to move the turbines which in turn run the electric generators. The energy of water utilised for power generation may be kinetic or potential. The kinetic energy of water is its energy in motion and is a function of mass and velocity, while the potential energy is a function of the difference in level/ head of water between two points.

In either case continuous availability of water is a basic necessity; to ensure this, water collected in natural lakes and reservoirs at high altitudes may be utilised or water may be artificially stored by constructing dams across flowing streams.

The ideal site is one in which a good system of natural lakes with substantial catchment area, exists at a high altitude. Rainfall is the primary source of water and depends upon such factors as temperature, humidity, cloudiness, wind etc. The usefulness of rainfall for power purposes further depends upon several complex factors which include its intensity, time distribution, topography of land etc.

However, it has been observed that only a small part of the rainfall can actually be utilised for power generation. A significant part is accounted for by direct evaporation, while another similar quantity seeps into the soil and forms the underground storage. Some water is also absorbed by vegetation. Thus, only a part of water falling as rain actually flows over the ground surface as direct run off and forms the streams which can be utilised for hydro- schemes.

i. First hydro-electric station was probably started in America in 1882 and thereafter development took place very rapidly. In India the first major hydroelectric development of 4.5 MW capacity named as Sivasamudram Scheme in Mysore was commissioned in 1902. In 1914 a hydropower plant named Khopali project of 50 MW capacity was commissioned in Maharashtra. The hydro-power capacity, upto 1947, was nearly 500 MW.

ii. Hydro (water) power is a conventional renewable source of energy which is clean, free from pollution and generally has a good environmental effect.

However the following factors are major obstacles in the utilisation of hydro-power resources:

(i) Large investments

(ii) Long gestation period

(iii) Increased cost of power transmission.

Next to thermal power, hydro-power is important in regard to power generation. The hydro-electric power plants provide 30 per cent of the total power of the world. The total hydro-potential of the world is about 5000 GW. In some countries (like Norway) almost total power generation is hydro-based.

Essay # 2. Selection of Site for a Hydro-Electric Plant:

The following factors should be considered while selecting the site for a hydro-electric plant:

a. Availability of water

b. Water storage

c. Water head

d. Accessibility of the site

e. Distance from load centre

f. Type of the land of site.

a. Availability of Water:

The most important aspect of hydro-electric plant is the availability of water at the site since all other designs are based on it. Therefore the run-off data at the proposed site must be available beforehand. It may not be possible to have run-off data at the proposed site but data concerning the rainfall over the large catchment area is always available. Estimate should be made about the average quantity of water available throughout the year and also about maximum and minimum quantity of water available during the year.

These details are necessary to:

(i) Decide the capacity of the hydro-electric plant,

(ii) Setting up of peak load plant such as steam, diesel or gas turbine plant and to,

(iii) Provide adequate spillways or gate relief during the flood period.

b. Water Storage:

Since there is a wide variation in rainfall during the year, therefore, it is always necessary to store the water for continuous generation of power. The storage capacity can be calculated with the help of mass curve. Maximum storage should justify the expenditure on the project.

The two types of storages in use are:

(i) The storage is so constructed that it can make water available for power generation of one year only. In this case storage becomes full in the beginning of the year and becomes empty at the end of each year.

(ii) The storage is so constructed that water is available in sufficient quantity even during the worst dry periods.

c. Water Head:

In order to generate a requisite quantity of power it is necessary that a large quantity of water at a sufficient head should be available. An increase in effective head, for a given output, reduces the quantity of water required to be supplied to the turbines.

d. Accessibility of the Site:

The site where hydro-electric plant is to be constructed should be easily accessible. This is important if the electric power generated is to be utilised at or near the plant site. The site selected should have transportation facilities of rail and road.

e. Distance from the Load Centre:

It is of paramount importance that the power plant should be set up near the load centre; this will reduce the cost of erection and maintenance of transmission line.

f. Type of the Land of the Site:

The land to be selected for the site should be cheap and rocky. The ideal site will be one where the dam will have largest catchment area to store water at high head and will be economical in construction.

The necessary requirements of the foundation rocks for a masonry dam are as follows:

(i) The rock should be strong enough to withstand the stresses transmitted from the dam structure as well as the thrust of the water when the reservoir is full.

(ii) The rock in the foundation of the dam should be reasonably impervious.

(iii) The rock should remain stable under all conditions.

Essay # 3. Elements of Hydro-Electric Plant:

The following are the essential elements of hydro-electric power plant:

a. Catchment area

b. Reservoir

c. Dam

d. Spillways

e. Conduits

f. Surge tanks

g. Prime movers

h. Draft tubes

i. Power-house and equipment.

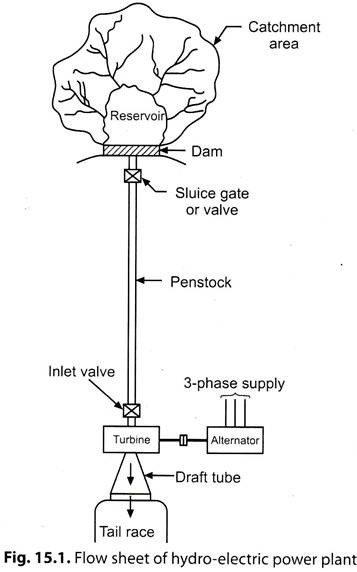

Fig. 15.1 shows the flow sheet of hydro-electric power plant.

Essay # 4. Classification of Hydro-Electric Plants:

Hydro-electric power stations may be classified as follows:

A. According to Availability of Head:

1. High head power plants

2. Medium head power plants

3. Low head power plants.

B. According to the Nature of Load:

1. Base load plants

2. Peak load plants.

C. According to the Quantity of Water Available:

1. Run-of-river plant without pondage

2. Run-of-river plant with pondage

3. Storage type plants

4. Pump storage plants

5. Mini and micro-hydel plants.

A. According to Availability of Head:

The following figures give a rough idea of the heads under which the various types of plants work:

(i) High head power plants 100 m and above

(ii) Medium head power plants 30 to 100 m

(iii) Low head power plants 25 to 80 m.

Note- It may be noted that figures given above overlap each other. Therefore it is difficult to classify the plants directly on the basis of head alone. The basis, therefore, technically adopted is the specific speed of the turbine used for a particular plant.

(i) High Head Power Plants:

These types of plants work under heads ranging from 100 to 2000 metres. Water is usually stored up in lakes on high mountains during the rainy season or during the season when the snow melts. The rate of flow should be such that water can last throughout the year.

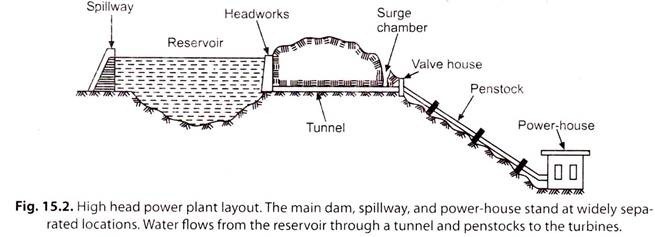

Fig. 15.2 shows high head power plant layout. Surplus water discharged by the spillway cannot endanger the stability of the main dam by erosion because they are separated. The tunnel through the mountain has a surge chamber excavated near the exit. Flow is controlled by head gates at the tunnel intake, butterfly valves at the top of the penstocks, and gate valves at the turbines. This type of site might also be suitable for an underground station.

The Pelton wheel is the common primemover used in high head power plants.

(ii) Medium Head Power Plants:

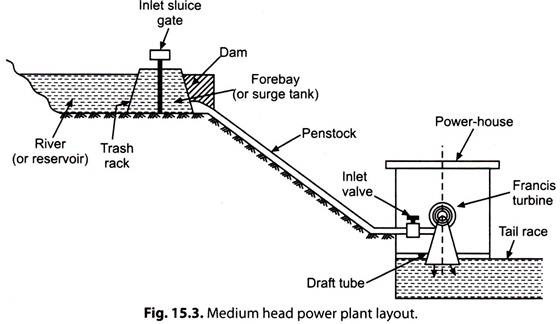

Refer to Fig. 15.3. When the operating head of water lies between 30 to 100 metres, the power plant is known as medium head power plant. This type of plant commonly uses Francis turbines. The forebay provided at the beginning of the penstock serves as the water reservoir. In such plants, the water is generally carried in open canals from main reservoir to the forebay and then to the power-house through the penstock. The forebay itself works as a surge tank in this plant.

(iii) Low Head Power Plants:

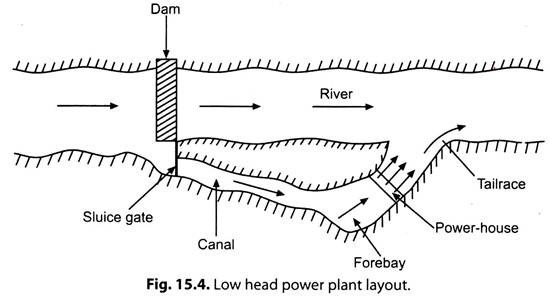

Refer to Fig. 15.4. These plants usually consist of a dam across a river. A side way stream diverges from the river at the dam. Over this stream the power-house is constructed. Later this channel joins the river further downstream. This type of plant uses vertical shaft Francis turbine or Kaplan turbine.

B. According to Nature of Load:

(i) Base Load Plants:

The plants which cater to the base load of the system are called base load plants. These plants are required to supply a constant power when connected to the grid. Thus they run without stop and are often remote-controlled with which least staff is required for such plants. Run-of-river plants without pondage may sometimes work as base load plant, but the firm capacity in such cases, will be much less.

(ii) Peak Load Plants:

The plants which can supply the power during peak loads are known as peak load plants. Some of such plants supply the power during average load but also supply peak load as and when it is there ; whereas other peak load plants are required to work during peak load hours only. The run-of-river plants may be made for the peak load by providing pondage.

C. According to the Quantity of Water Available:

(i) Run-of-River Plants without Pondage:

A run-of-river plant without pondage, as the name indicates, does not store water and uses the water as it comes. There is no control on flow of water so that during high floods or low loads water is wasted while during low run-off the plant capacity is considerably reduced. Due to non-uniformity of supply and lack of assistance from a firm capacity the utility of these plants is much less than those of other types.

The head on which these plants work varies considerably. Such a plant can be made a great deal more useful by providing sufficient storage at the plant to take care of the hourly fluctuations in load.

This lends some firm capacity to the plant. During good flow conditions these plants may cater to base load of the system, when flow reduces they may supply the peak demands. Head water elevation for plant fluctuates with the flow conditions.

These plants without storage may sometimes be made to supply the base load, but the firm capacity depends on the minimum flow of river. The run-of-river plant may be made for load service with pondage, though storage is usually seasonal.

(ii) Run-of-River Plants with Pondage:

Pondage usually refers to the collection of water behind a dam at the plant and increases the stream capacity for a short period, say a week. Storage means collection of water in upstream reservoirs and this increases the capacity of the stream over an extended period of several months. Storage plants may work satisfactorily as base load and peak load plants.

This type of plant, as compared to that without pondage, is more reliable and its generating capacity is less dependent on the flow rates of water available.

(iii) Storage Type Plants:

A storage type plants is one with a reservoir of sufficiently large size to permit carry-over storage from the wet reason to the dry reason, and thus to supply firm flow substantially more than the minimum natural flow. This plant can be used as base load plant as well as peak load plant as water is available with control as required. The majority of hydro-electric plants are of this type.

(iv) Pumped Storage Plants:

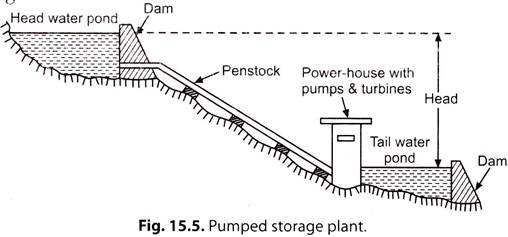

Refer to Fig. 15.5.

Pumped storage plants are employed at the places where the quantity of water available for power generation is inadequate. Here the water passing through the turbines is stored in ‘tail race pond’. During low load periods this water is pumped back to the head reservoir using the extra energy available.

This water can be again used for generating power during peak load periods. Pumping of water may be done seasonally or daily depending upon the conditions of the site and the nature of the load on the plant.

Such plants are usually interconnected with steam or diesel engine plants so that off peak capacity of interconnecting stations is used in pumping water and the same is used during peak load periods. Of course, the energy available from the quantity of water pumped by the plant is less than the energy input during pumped operation. Again while using pumped water the power available is reduced on account of losses occurring in prime-movers.

Advantages of Pump Storage Plants:

The pump storage plants entail the following advantages:

1. There is substantial increase in peak load capacity of the plant at comparatively low capital cost.

2. Due to load comparable to rated load on the plant, the operating efficiency of the plant is high.

3. There is an improvement in the load factor of the plant.

4. The energy available during peak load periods is higher than that of during off peak periods so that inspite of losses incurred in pumping there is overall gain.

5. Load on the hydro-electric plant remains uniform.

6. The hydro-electric plant becomes partly independent of the stream flow conditions.

Under pump storage projects almost 70 percent power used in pumping the water can be recovered. In this field the use of “Reversible Turbine Pump” units is also worth noting. These units can be used as turbine while generating power and as pump while pumping water to storage.

The generator in this case works as motor during reverse operation. The efficiency in such case is high and almost the same in both the operations. With the use of reversible turbine pump sets, additional capital investment on pump and its motor can be saved and the scheme can be worked more economically.

(v) Mini and Micro-Hydel Plants:

In order to meet with the present energy crisis partly, a solution is to develop mini (5m to 20m head) and micro (less than 5 m head) hydel potential in our country. The low head hydro-potential is scattered in this country and estimated potential from such sites could be as much as 20,000 MW.

By proper planning and implementation, it is possible to commission a small hydro- generating set up of 5 MW within a period of one and half year against the period of a decade or two for large capacity power plants. Several such sets upto 1000 kW each have been already installed in Himachal Pradesh, U.P., Arunachal Pradesh, West Bengal and Bhutan.

To reduce the cost of micro-hydel stations than that of the cost of conventional installation the following considerations are kept in view:

1. The civil engineering work needs to be kept to a minimum and designed to fit in with already existing structures e.g., irrigation, channels, locks, small dams etc.

2. The machines need to be manufactured in a small range of size of simplified design, allowing the use of unified tools and aimed at reducing the cost of manufacture.

3. These installations must be automatically controlled to reduce attending personnel.

4. The equipment must be simple and robust, with easy accessibility to essential parts for maintenance.

5. The units must be light and adequately sub-assembled for ease of handling and transport and to keep down erection and dismantling costs.

Micro-hydel plants (micro-stations) make use of standardised bulb sets with unit output ranging from 100 to 1000 kW working under heads between 1.5 to 10 metres.

Essay # 5. Advantages and Disadvantages of Hydro-Electric Plants:

Advantages of Hydro-Electric Plant:

1. No fuel charges.

2. An hydro-electric plant is highly reliable.

3. Maintenance and operation charges are very low.

4. Running cost of the plant is low.

5. The plant has no stand by losses.

6. The plant efficiency does not change with age.

7. It takes a few minutes to run and synchronise the plant.

8. Less supervising staff is required.

9. No fuel transportation problem.

10. No ash problem and atmosphere is not polluted since no smoke is produced in the plant.

11. In addition to power generation these plants are also used for flood control and irrigation purposes.

12. Such a plant has comparatively a long life (100-125 years as against 20-45 years of a thermal plant).

13. The number of operations required is considerably small compared with thermal power plants.

14. The machines used in hydro-electric plants are more robust and generally run at low speeds at 300 to 400 r.p.m. where the machines used in thermal plants run at a speed 3000 to 4000 r.p.m. Therefore, there are no specialised mechanical problems or special alloys required for construction.

15. The cost of land is not a major problem since the hydro-electric stations are situated away from the developed areas.

Disadvantages of Hydroelectric Plant:

1. The initial cost of the plant is very high.

2. It takes considerable long time for the erection of such plants.

3. Such plants are usually located in hilly areas far away from the load centre and as such they require long transmission lines to deliver power, subsequently the cost of transmission lines and losses in them will be more.

4. Power generation by the hydro-electric plant is only’ dependent on the quantity of water available which in turn depends on the natural phenomenon of rain. So if the rainfall is in time and proper and the required amount of water can be collected, the plant will function satisfactorily otherwise not.

Essay # 6. Application of Hydro-Electric Plants:

Earlier hydro-electric plants have been used as exclusive source of power, but the trend is towards use of hydropower in an interconnected system with thermal stations. As a self-contained and independent power source, a hydro-plant is most effective with adequate storage capacity, otherwise the maximum load capacity of the station has to be based on minimum flow of stream and there is a great wastage of water over the dam for greater part of the year. This increases the per unit cost of installation.

By interconnecting hydro-power with steam, a great deal of saving in cost can be effected due to:

(i) Reduction in necessary reserve capacity,

(ii) Diversity in construction programmes,

(iii) Higher utilisation factors on hydroplants, and

(iv) Higher capacity factors on efficient steam plants.

In an interconnected system the base load is supplied by hydropower when the maximum flow demand is less than the stream flow while steam supplies the peak. When stream flow is lower than the maximum demand the hydroplant supplies the peak load and steam plant the base load.