Are you looking for an essay on ‘Diesel Power Plant’? Find paragraphs, long and short essays on ‘Diesel Power Plant’ especially written for school and college students.

Essay on Diesel Power Plant

Essay Contents:

- Essay on the Introduction to Diesel Power Plant

- Essay on the Site Selection for Diesel Power Plant

- Essay on the Heat Engines Used in Diesel Power Plant

- Essay on the Operation of a Diesel Power Plant

- Essay on the Components of Diesel Power Plant

- Essay on the Types of Diesel Engines Used for Diesel Power Plants

- Essay on the Layout of a Diesel Power Plant

- Essay on the Advantages and Disadvantages of Diesel Power Plants

- Essay on the Applications of Diesel Power Plant

Essay # 1. Introduction to Diesel Power Plant:

i. Diesel engine power plants are installed where supply of coal and water is not available in sufficient quantity or where power is to be generated in small quantity or where standby sets are required for continuity of supply such as in hospitals, telephone exchanges, radio stations and cinemas.

These plants in the range of 2 to 50 MW capacity are used as central stations for supply authorities and works and they are universally adopted to supplement hydro-electric or thermal stations where standby generating plants are essential for starting from cold and under emergency conditions.

ii. In several countries, the demand for diesel power plants is increased for electric power generation because of difficulties experienced in construction of new hydraulic plants and enlargement of old hydro-plants. A long term planning is required for the development of thermo and hydro-plants which cannot keep the pace with many times the increased demand by the people and industries.

iii. The diesel units used for electric generation are more reliable and long-lived piece of equipment compared with other types of plants.

Essay # 2. Site Selection for Diesel Power Plant:

The following factors should be considered while selecting the site for a diesel power plant:

1. Foundation sub-soil condition:

The conditions of sub-soil should be such that a foundation at a reasonable depth should be capable of providing a strong support to the engine.

2. Access to the site:

The site should be so selected that it is accessible through rail and road.

3. Distance from the load centre:

The location of the plant should be near the load centre. This reduces the cost of transmission lines and maintenance cost. The power loss is also minimised.

4. Availability of water:

Sufficient quantity of water should be available at the site selected.

5. Fuel transportation:

The site selected should be near to the source of fuel supply so that transportation charges are low.

Essay # 3. Heat Engines Used in Diesel Power Plant:

Any type of engine or machine which derives heat energy from the combustion of fuel or any other sources and converts this energy into mechanical work is termed as a heat engine.

Heat engines may be classified into two main classes as follows:

1. External Combustion Engines

2. Internal Combustion Engines

1. External combustion engines (E.C. engines):

In this case, combustion of fuel takes place outside the cylinder as in case of steam engines where the heat of combustion is employed to generate steam which is used to move a piston in a cylinder. Other examples of external combustion engines are hot air engines, steam turbine and closed cycle gas turbine. These engines are generally used for driving locomotives, ships, generation of electric power etc.

2. Internal combustion engines (I.C. engines):

In this case, combustion of the fuel with oxygen of the air occurs within the cylinder of the engine. The internal combustion engines group includes engines employing mixtures of combustible gases and air, known as gas engines those using lighter liquid fuel or spirit known as petrol engines and those using heavier liquid fuels, known as oil compression ignition or diesel engines.

Classification of I.C. engines:

Internal combustion engines may be classified as given below:

a. According to cycle of operation:

(i) Two stroke cycle engines

(ii) Four stroke cycle engines.

b. According to cycle of combustion:

(i) Otto cycle engine (combustion at constant volume)

(ii) Diesel cycle engine (combustion at constant pressure)

(iii) Dual-combustion or Semi-Diesel cycle engine (combustion partly at constant volume and partly at constant pressure).

c. According to arrangement of cylinder:

(i) Horizontal engine

(ii) Vertical engine

(iii) V-type engine

(iv) Radial engine etc.

d. According to their uses:

(i) Stationary engine

(ii) Portable engine

(iii) Marine engine

(iv) Automobile engine

(v) Aero engine etc.

e. According to the fuel employed and the method of fuel supply to the engine cylinder:

(i) Oil engine

(ii) Petrol engine

(iii) Gas engine

(iv) Kerosene engine etc.

(v) Carburettor, hot bulb, solid injection and air injection engine.

f. According to the speed of the engine:

(i) Low speed engine

(ii) Medium speed engine

(iii) High speed engine.

g. According to method of ignition:

(i) Spark ignition (S.I.) engine

(ii) Compression ignition (C.I.) engine,

h. According to method of cooling the cylinder:

(i) Air-cooled engine

(ii) Water-cooled engine.

i. According to method of governing:

(i) Hit and miss governed engine

(ii) Quality governed engine

(iii) Quantity governed engine.

j. According to valve arrangement:

(i) Over head valve engine

(ii) L-head type engine

(iii) T-head type engine

(iv) F-head type engine.

k. According to number of cylinders:

(i) Single cylinder engine

(ii) Multi-cylinder engine.

Essay # 4. Operation of a Diesel Power Plant:

When diesel alternator sets are put in parallel, “hunting” or “phase swinging” may be produced due to resonance unless due care is taken in the design and manufacture of the sets. This condition occurs due to resonance between the periodic disturbing forces of the engine and natural frequency of the system.

The engine forces results from uneven turning moment on the engine crank which are corrected by the flywheel effect. “Hunting” results from the tendency of each set trying to pull the other into synchronism and is characterised by flickering of lights.

To ensure most economical operation of diesel engines of different sizes when working together and sharing load it is necessary that they should carry the same percentage of their full load capacity at all times as the fuel consumption would be lowest in this condition. For best operation performance the manufacturer’s recommendations should be strictly followed.

In order to get good performance of a diesel power plant the following points should be taken care of:

1. It is necessary to maintain the cooling temperature within the prescribed range and use of very cold water should be avoided. The cooling water should be free from suspended impurities and suitably treated to be scale and corrosion free. If the ambient temperature approaches freezing point, the cooling water should be drained out of the engine when it is kept idle.

2. During operation the lubrication system should work effectively and requisite pressure and temperature maintained. The engine oil should be of the correct specifications and should be in a fit condition to lubricate the different parts. A watch may be kept on the consumption of lubricating oil as this gives as indication of the true internal condition of the engine.

3. The engine should be periodically run even when not required to be used and should not be allowed to stand idle for more than 7 days.

4. Air filter, oil filters and fuel filters should be periodically serviced or replaced as recommended by the manufacturers or if found in an unsatisfactory condition upon inspection.

5. Periodical checking of engine compression and firing pressures and also exhaust temperatures should be made.

i. The engine exhaust usually provides a good indication of satisfactory performance of the engine. A black smoke in the exhaust is a sign of inadequate combustion or engine overloading.

ii. The loss of compression resulting from wearing out of moving parts lowers the compression ratio causing inadequate combustion. These defects can be checked by taking indicator diagrams of the engine after reasonable intervals.

Essay # 5. Components of a Diesel Power Plant:

The essential components of a diesel power plant are discussed as follows:

a. Engine:

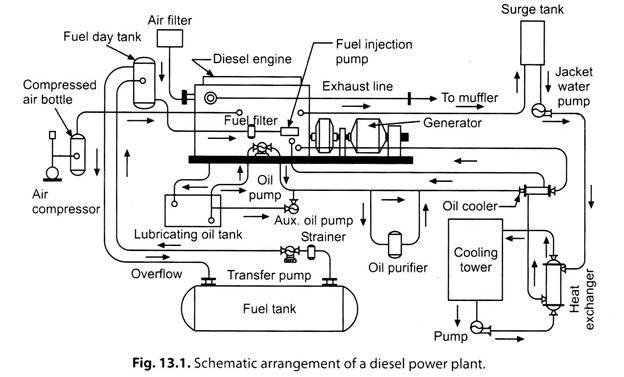

This is the main component of the plant which develops the required power. It is generally directly coupled to the generator as shown in Fig. 13.1.

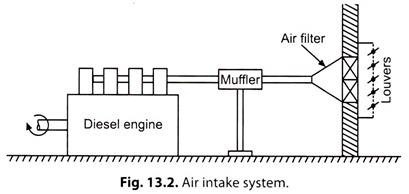

b. Air Intake System:

The air intake system conveys fresh air through pipes or ducts to:

(i) Air intake manifold of four stroke engines

(ii) The scavenging pump inlet of a two stroke engine and

(iii) The supercharger inlet of a supercharged engine.

The air system begins with an intake located outside the building provided with a filter to catch dirt which would otherwise cause excessive wear in the engine. The filters may be of dry or oil bath. Electrostatic precipitator filters can also be used.

Oil impingement type of filter consists of a frame filled with metal shavings which are coated with a special oil so that the air in passing through the frame and being broken up into a number of small filaments comes into contact with the oil whose property is to seize and hold any dust particles being carried by the air.

The dry type of filter is made of cloth, felt, glass wool etc. In case of oil bath type of filter the air is swept over or through a pool of oil so that the particles of dust become coated. Light weight steel pipe is the material for intake ducts. In some cases, the engine noise may be transmitted back through the air intake system to the outside air. In such cases a silencer is provided between the engine and the intake.

Following precautions should be taken while constructing a suitable air intake system:

1. Air intakes may not be located inside the engine room.

2. Air should not be taken from a confined space otherwise air pulsations can cause serious vibration problems.

3. The air-intake line used should neither have too small a diameter nor should be too long, otherwise there may crop up engine starvation problem.

4. Air intake filters may not be located close to the roof of the engine room otherwise pulsating air flow through the filters can cause serious vibrations of the roof.

5. Air intake filters should not be located in an inaccessible location.

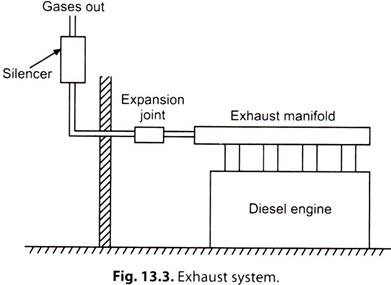

c. Exhaust System:

Refer to Fig. 13.3. The purpose of the exhaust system is to discharge the engine exhaust to the atmosphere outside the building. The exhaust manifold connects the engine cylinder exhausts outlets to the exhaust pipe which is provided with a muffler to reduce pressure in the exhaust line and eliminate most of the noise which may result if gases are discharged directly into the atmosphere.

The exhaust pipe leading out of the building should be short in length with minimum number of bends and should have one or two flexible tubing sections which take up the effects of expansion, and isolate the system from the engine vibration. Every engine should be provided with its independent exhaust system.

The waste heat utilisation in a diesel-steam station may be done by providing waste- heat boilers in which most of the heat of exhaust gases from the engine is utilised to raise low pressure steam. Such application is common on marine plants.

On the stationary power plant the heat of exhaust may be utilised to heat water in gas-to-water heat exchangers consisting of a water coil placed in exhaust muffler and using the water in the plant suitably. If air heating is required, the exhaust pipe from the engine is surrounded by the cold air jacket, and transfers the heat of exhaust gases to the air.

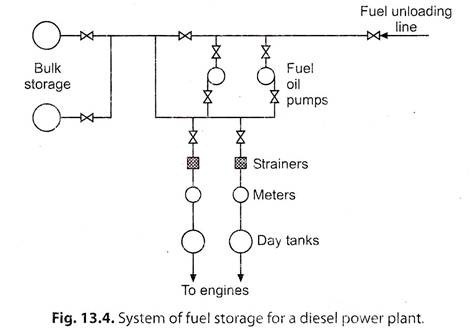

d. Fuel System:

The fuel oil may be delivered at the plant site by trucks, railroad tank cars or barge and tankers. From tank car or truck the delivery is through the unloading facility to main storage tanks and then by transfer pumps to small service storage tanks known as engine day tanks. Large storage capacity allows purchasing fuel when prices are low. Refer to Fig. 13.4.

The main flow is made workable and practical by arranging the piping equipment with the necessary heaters, by passes, shut-offs, drain lines, relief valves, strainers and filters, flow meters and temperature indicators. The actual flow plans depend on type of fuel, engine equipment, size of the plant etc.

The tanks should contain manholes for internal access and repair, fill lines to receive oil, vent lines to discharge vapours, overflow return lines for controlling oil flow and a suction line to withdraw oil. Coils heated by hot water or steam reduce oil viscosity to lower pumping power needs.

The minimum storage capacity of at least a month’s requirement of oil should be kept in bulk, but where advantage of seasonal fluctuations in cost of oil is to be availed, it may be necessary to provide storage for a few months requirements. Day tanks supply the daily fuel need of engines and may contain a minimum of about 8 hours of oil requirement of the engines. These tanks are usually placed high so that oil may flow to engines under gravity.

For satisfactory operation of a fuel oil supply system the following points should be taken care of:

1. There should be provisions for cleanliness and for changing over of lines during emergencies.

2. In all suction lines the pipe joints should be made tight.

3. Before being covered all oil lines should be put under air pressure and the joints tested with soap solution. Small air leaks into the line can be the sources of exasperating operating difficulties and are hard to remedy once the plant is in operation.

4. The piping between filter and the engine should be thoroughly oil flushed before being first placed in service.

5. Considerable importance should be given for cleanliness in handling bulk fuel oil. Dirt particles will ruin the fine lap of injection pumps or plug the injection nozzle orifices. So high-grade filters are of paramount importance to the diesel oil supply system.

Fuel injection system:

The mechanical heart of the Diesel engine is the fuel injection system. The engine can perform no better than its fuel injection system. A very small quantity of fuel must be measured out, injected, atomised, and mixed with combustion air.

The mixing problem becomes more difficult—the larger the cylinder and faster the rotative speed. Fortunately the high-speed engines are the small bore automotive types; however, special combustion arrangements such as pre-combustion chambers, air cells, etc., are necessary to secure good mixing. Engines driving electrical generators have lower speeds and simple combustion chambers.

Functions of a fuel injection system:

1. Filter the fuel.

2. Meter or measure the correct-quantity of fuel to be injected.

3. Time the fuel injection.

4. Control the rate of fuel injection.

5. Atomise or break up the fuel to fine particles.

6. Properly distribute the fuel in the combusion chamber.

The injection system are manufactured with great accuracy, especially the parts that actually meter and inject the fuel. Some of the tolerances between the moving parts are very small of the order of one micron. Such closely fitting parts require special attention during manufacture and hence the injection systems are costly.

Types of fuel injection systems:

The following fuel injection systems are commonly used in diesel power station:

1. Common-rail injection system.

2. Individual pump injection system.

3. Distributor.

Atomisation of fuel oil has been secured by:

(i) Air blast and

(ii) Pressure spray.

Early diesel engines used air fuel injection at about 70 bar. This is sufficient not only to inject the oil, but also to atomise it for a rapid and thorough combustion. The expense of providing an air compressor and tank lead to the development of “solid” injection, using a liquid pressure of between 100 and 200 bar which is sufficiently high to atomise the oil it forces through spray nozzles. Great advances have been made in the field of solid injection of the fuel through research and progress in fuel pump, spray nozzles, and combustion chamber design.

Essay # 6. Types of Diesel Engines Used for Diesel Power Plants:

The diesel engines may be four-stroke or two stroke cycle engines. The two-stroke cycle engines are favoured for diesel power plants.

Efforts are being made to use “dual fuel engines” in diesel power plants for better economy and proper use of available gaseous fuels in the country. The gas may be a waste product as in the case of sewage treatment installations or oil fuels where the economic advantage is self-evident. With the wider availability of natural gas, the dual fuel engines may become an attractive means of utilising gas as fuel at off-peak tariffs for the electric power generation.

Working of dual fuel engines:

The various strokes of a dual fuel engine are as follows:

1. Suction stroke. During this stroke air and gas are drawn in the engine cylinder.

2. Compression stroke. During this stroke the pressure of the mixture drawn is increased. Near the end of this stroke the ‘pilot oil’ is injected into the engine cylinder. The compression heat first ignites the pilot oil and then gas mixture.

3. Working/Power stroke. During this stroke the gases (at high temperature) expand and thus power is obtained.

4. Exhaust stroke. The exhaust gases are released to the atmosphere during the stroke.

Essay # 7. Layout of a Diesel Power Plant:

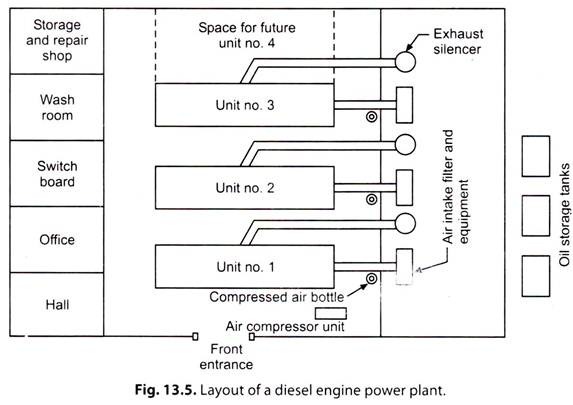

Fig. 13.5 shows the layout of a diesel engine power plant.

The most common arrangement for diesel engines is with parallel centre lines, with some room left for extension in future. The repairs and usual maintenance works connected with such engines necessitate sufficient space around the units and consideration should be given to the need for dismantling and removal of large components of the engine generator set.

The air intakes and filters as well as the exhaust mufflers are located outside the building or may be separated from the main engine room by a partition wall. The latter arrangement is not vibration free. Adequate space for oil storage and repair shop as well as for office should be provided close to the main engine room. Bulk storage of oil may be outdoor. The engine room should be well ventilated.

Essay # 8. Advantages and Disadvantages of Diesel Power Plants:

The advantages and disadvantages of diesel power plants are listed below:

Advantages of diesel power plant:

1. Design and installation are very simple.

2. Can respond to varying loads without any difficulty.

3. The standby losses are less.

4. Occupy less space.

5. Can be started and put on load quickly.

6. Require less quantity of water for cooling purposes.

7. Overall capital cost is lesser than that for steam plants.

8. Require less operating and supervising staff as compared to that for steam plants.

9. The efficiency of such plants at part loads does not fall so much as that of a steam plant.

10. The cost of building and civil engineering works is low.

11. Can burn fairly wide range of fuels.

12. These plants can be located very near to the load centres, many times in the heart of the town.

13. No problem of ash handling.

14. The lubrication system is more economical as compared with that of a steam power plant.

15. The diesel power plants are more efficient than steam power plants in the range of 150 MW capacity.

Disadvantages of diesel power plant:

1. High operating cost.

2. High maintenance and lubrication cost.

3. Diesel units capacity is limited. These cannot be constructed in large size.

4. In a diesel power plant noise is a serious problem.

5. Diesel plants cannot supply overloads continuously whereas steam power plant can work under 25% overload continuously.

6. The diesel power plants are not economical where fuel has to be imported.

7. The life of a diesel power plant is quite small (2 to 5 years or less) as compared to that of a steam power plant (25 to 30 years).

Essay # 9. Applications of Diesel Power Plant:

The diesel power plants find wide application in the following fields:

1. Peak load plant

2. Mobile plants

3. Standby units

4. Emergency plant

5. Nursery station

6. Starting stations

7. Central stations—where capacity required is small (5 to 10 MW)

8. Industrial concerns where power requirement is small, say of the order of 500 kW, diesel power plants become more economical due to their higher overall efficiency.