Are you looking for an essay on ‘Pollution Caused by Various Power Plants’? Find paragraphs, long and short essays on ‘Pollution Caused by Various Power Plants’ especially written for school and college students.

Essay # 1. Pollution from Thermal-Power Plants:

The environment is polluted to a great extent by thermal power plants. The emission from the chimney throws unwanted gases and particles into the atmosphere while the heat is thrown into the atmosphere and rivers. Both these aspects pollute the environment beyond tolerable limits and now are being controlled by appropriate regulations. The types of emissions, effects and methods of minimising these pollutions are discussed below.

The air pollution in a large measure is caused by the thermal-power plants burning conventional fuels (coal, oil or gas). The combustible elements of the fuel are converted to gaseous products and non-combustible elements to ash.

Thus the emission can be classified as follow:

I. Gaseous emission.

II. Particulate emission.

III. Solid waste emission.

IV. Thermal pollution (or waste heat).

I. Gaseous Emission and Its Control:

The various gaseous pollutants are:

(i) Sulphur dioxide

(ii) Hydrogen sulphide

(iii) Oxides of nitrogen

(iv) Carbon monoxide etc.

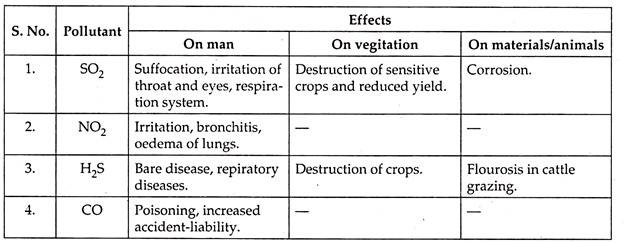

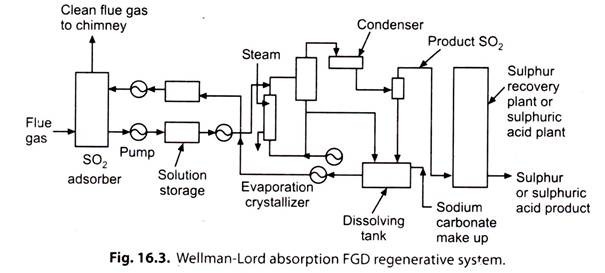

The effects of pollutants on environment are as follows:

Removal of Sulphur Dioxide (SO2):

SO2 is removed by wet scrubbers as shown in Fig. 16.1.

i. The gases to be cleaned are admitted tangentially into the scrubber which will also help in separating the particulate matters. Water spray absorbs these gases, and particulate matters which collect on the surface of the scrubber, are washed down by the water and this water is further treated, filtered and reused.

ii. The wet scrubbers also find application in chemical and grain milling industries.

iii. The collection efficiency of scrubber is about 90 per cent.

Disadvantages of Using Wet Scrubbers:

The following are the disadvantages of using wet scrubbers:

1. The gases are cooled to such an extent that they must be reheated before being sent to the stack.

2. The pressure drops are very high.

3. Water used, after dissolving sulphur oxides, will contain sulphuric and sulphurous acids which may corrode the pipelines and the scrubber itself. This water cannot be let out into the rivers for obvious reasons.

In power plants where high sulphur content coal is the only source available, it is preferable to remove the sulphur from the coal before it is burnt. This is done by coal washing which reduces the flyash as well as some sulphur oxides in the flue gases. But the power plants employ “Flue-gas desulphurization” (FGD) system similar to wet scrubber system.

FGD can be of the following types:

1. The recovery or regenerative system.

2. Throw away or non-regenerative system. In this system the reactants are not recovered and the final products are sulphur salts of calcium and magnesium.

Regenerative System:

Some of the regenerative systems are:

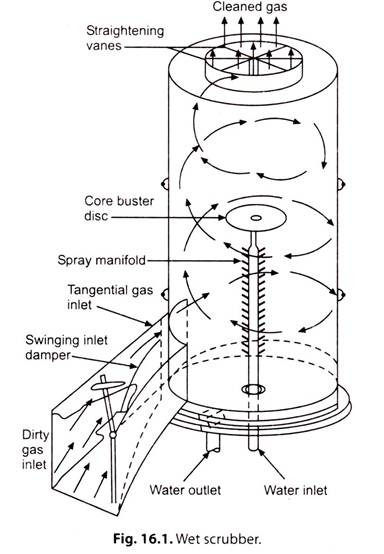

1. FW-Bergbau process.

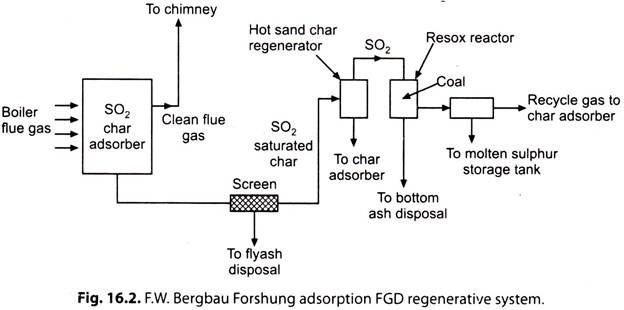

2. Wellman-Lord process.

3. Wet magnesium oxide process.

i. In the Fig. 16.2 is shown the FW-Bergbau process. In this process, S02 is removed by adsorption and sulphur is collected as molten sulphur.

ii. Fig. 16.3 shows the Wellman-Lord FGD system. This system removes SO2 by absorption in sodium carbonate and SO2 is recovered as sulphur or sulphuric acid products.

In non-regenerative systems the principal reactant is either lime or limestone. The slurry is made into sludge by adding flyash and other proprietary sludge additives and the sludge is disposed. This method could prove a bit more expensive since no sulphur or sulphur product is recovered and the reactant is not generated as in the case of FW Bergbau porcess.

Emission of NOx:

Nitrogen oxides are compounds of the elements nitrogen and oxygen, both of which are present in air. The combustion of fossil fuels in air is accompanied by the formation of nitric oxide (NO) which is subsequently partly oxidised to nitrogen dioxide (NO2). The resulting mixture of variable combustion is represented by the symbol NOx, where x has a value between 1 and 2. Nitrogen oxides are present in stack gases from coal, oil and gas furnaces (and also in the exhaust gases from internal combustion engines and gas turbines).

The following methods are commonly used to reduce the emission of NOx from thermal (and gas turbine) power plants:

1. Reduction of temperature in combustion zone.

2. Reduction of residence period in combustion zone.

3. Increase in equivalence ratio in the combustion zone.

II. Particulate Emission and Its Control:

The particulate emission, in power plants using fossil fuels, is easiest to control. Particulate matter can be either dust (Particles having a diameter of 1 micron) which do not settle down or particles with a diameter of more than 10 microns which settle down to the ground.

The particulate emission can be classified as follows:

i. Smoke:

It composes of stable suspension of particles that have a diameter of less than 10 microns and are visible only in the aggregate.

ii. Fumes:

These are very small particles resulting from chemical reactions and are normally composed of metals and metallic oxides.

iii. Flyash:

These are ash particles of diameters of 100 microns or less.

iv. Cinders:

These are ash particles of diameters of 100 microns or more. The above particulates, in any system of controlling the particulate emission, are to be effectively collected from the flue gases.

The performance parameters for any particulate remover are called the collection efficiency defined as:

For different systems the collector efficiency varies from 50 to 99%; for an electrostatic precipitator it is more than 90%.

Some collector systems, their efficiencies and their adaptability, are discussed in the following sub-articles:

Cinder Catchers:

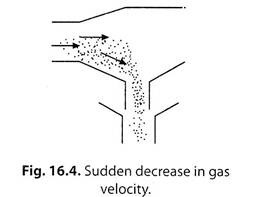

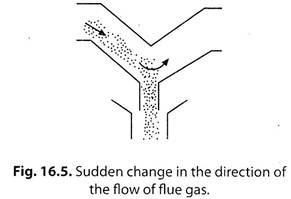

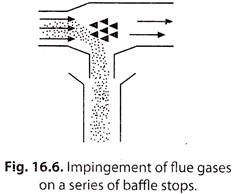

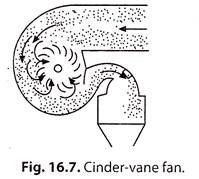

The cinder catchers are shown in Fig. 16.4 to 16.7.

a. Refer to Fig. 16.4. Sudden decrease in gas velocity makes the particulates separate and fall.

b. Refer to Fig. 16.5. A sudden change in the direction of flow of flue gas throws the particulates away and can be collected.

c. Refer to Fig. 16.6. Impingement of flue gases on a series of baffle stops the particulate matter as shown. These are commonly used in stoker and small cyclone furnaces where crushed coal is burned rather than the very fine pulverised coal. The collection efficiencies of cinder catchers are from 50 to 75%.

d. Refer to Fig. 16.7. Cinder-vane fan. The cinder-vane fan uses the fan which imparts centrifugal force to the particulates and they are collected as shown. The efficiency is from 50 to 75%

v. Wet Scrubbers:

a. Wet scrubbers as described for removal of gases can also be used for removal of particulate matters; but the gases will have to be reheated before they are sent to the stack.

b. The wet scrubbers are not commonly used to remove particulate matters.

vi. Electrostatic Precipitator:

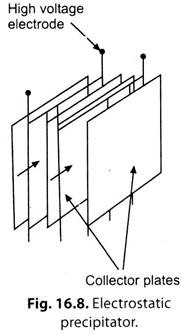

An electrostatic precipitator is shown in Fig. 16.8. In this device a very high voltage of 30 kV to 60 kV is applied to the wires suspended in a gas-flow passage between two grounded plates.

The particles in the gas stream acquire a charge from the negatively charged wires and are then attracted to the ground plates.

The grounded plates are periodically rapped by a steel plug which is raised and dropped by an electromagnet and dust is collected in the hoppers below:

i. In this type of collector, care must be taken to see that large quantity of unburnt gases do not enter the precipitator. If such a mixture enters, power should be turned off otherwise there could be explosion because of constant sparking between wires and plates.

ii. The collection efficiency is about 99 per cent.

iii. Electrostatic precipitators are suitable for power plants where flyash content is high. Flyash having high electrical resistivity does not separate in the electrostatic precipitator. This problem can be solved by injecting sulphur trioxide into the exhaust gas which improves the conductivity of flyash. This again poses a problem of discharging objectionable sulphur trioxide into the atmosphere; this needs a wet scrubber after the electrostatic precipitator.

vii. Baghouse Filters:

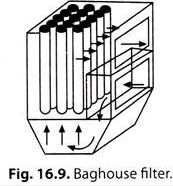

Fig. 16.9 shows a baghouse filter. Baghouse filters are found useful in removing the particulate matters where low sulphur coal is used.

i. The cloth filters cost about 20 per cent of installation cost and last for 1½ to 3 years.

ii. The baghouse filter is usually cleaned by forcing air in the reversed direction. They need large filter areas of about 6.5 m2/MW of power generation. Hence the installation cost could be high.

iii. Although baghouse filters are expensive, yet they are being widely used in coal- fired systems.

III. Solid Waste Disposal:

From the fossil fuel fired power plants considerable amount of solids in the form of ash is discharged. This ash is removed as bottom ash or slug from the furnace. The fossil fuel fired system also discharges solid wastes such as calcium and magnesium salts generated by absorption of SO2 and SO3 by reactant like limestone.

IV. Thermal Pollution:

Discharge of thermal energy into waters is commonly called ‘Thermal pollution’.

Thermal power stations invariably will have to discharge enormous amounts of energy into water since water is one medium largely used to condense steam. If this heated water from condensers is discharged into lakes or rivers, the water temperature goes up. The ability of water to hold dissolved gases goes down when the temperature increases.

At about 35°C, the dissolved oxygen will be so low that the aquatic life will die. But in very cold regions, letting out hot water into the lakes or rivers helps in increasing the fish growth. But, in our country, such places are not many and hence, it is necessary that we minimise this thermal pollution of water. One of the regulations stipulates that a maximum temperature of water let out can be 1°C above the atmospheric temperature. Thus the thermal-power plants or any other industry has to resort to various methods of adhering to this regulation.

Thermal Discharge Index (TDI):

Thermal discharge index (TDI) is the term usually used in connection with the estimation of the amount of thermal energy released to environment from a thermal-power plant. TDI of any power plant is the number of thermal energy units discharged to the environment for ever unit of electrical energy generated.

This index cannot be zero or else the plant violates the Second law of thermodynamics; but this index should be as low as possible to improve the efficiency of the plant as well as to keep the pollution level low.

The thermal discharge index (TDI) is strongly dependent on the thermal efficiency of the plant.

Reduction of Thermal Pollution:

While considering the efficiency of the thermal plant, it is desirable that the water from a river or lake is pumped through the condenser and fed back to the source. The rise of temperature will be about 10° C which is highly objectionable from the pollution point of view.

Hence, this waste heat which is removed from the condenser will have to be thrown into the atmosphere and not into the water source in this direction following methods can be adopted:

1. Construction of a separate lake.

2. Cooling pond.

3. Cooling towers.

1. Construction of a Separate Lake:

A sufficiently large water storage in the form of a lake can be built and once-through cooling the condenser can be adopted. It the natural cooling of water from the lake is not sufficient, floating spray pumps can be employed.

This method improves the thermal efficiency of the plant but can prove expensive. Also, it may not always be possible to have a large enough lake artificially built.

2. Cooling Pond:

A cooling pond with continuously operating fountains can be adopted for smaller power plants. This will also serve as a beautifying feature of the power plant site.

3. Cooling Towers:

In order to throw heat into the atmosphere most power stations adopt the cooling towers. The hyperbolic shape given to the tower automatically induces air from the bottom to flow upwards and the water is cooled by coming in direct contact with the air. This is a natural convection cooling and is also called ‘wet-cooling tower’. The overall efficiency of such plants will be lower than those of the plants adopting once-through cooling system. There will be considerable vapour flumes escaping from the cooling towers. Sometime, make-up cooling water may be scarce. In such cases, dry cooling tower can be adopted. Dry cooling towers are much more expensive than wet cooling towers.

All cooling towers, whether dry or wet, are expensive and add to the initial investment of the plant. Small plants can adopt mechanical-draft systems using induced or forced draft systems. This helps in avoiding height to the cooling towers. Thus, the initial cost is reduced but the maintenance costs of mechanical-draft systems are high.

Essay # 2. Pollution from Nuclear Power Plants:

The various types of pollution from nuclear power plants are:

(i) Radioactive pollution.

(ii) Waste from reactor (solid, liquid, gases).

(i) Radioactive Pollution:

This is the most dangerous and serious type of pollution. This is due to radioactive elements and fissionable products in reactor. The best way to abate is the radioactive shield around the reactor.

(ii) Waste from Reactor:

Due to nuclear reactor reaction nuclear wastes (mixtures of various Beta and Gamma emitting radioactive isotopes with various half-lives) are produced which cannot be neutralised by any chemical method. If the waste is discharged in the atmosphere, air and water will be contaminated beyond the tolerable limits.

Some methods of storage or disposal of radioactive waste materials are discussed below:

1. Storage Tanks- The radioactive wastes can be buried underground (very deep below the surface) in corrosion resistance tanks located in isolated areas. With the passage of time these will become stable isotopes.

2. Dilution- After storing for a short time, low energy wastes are diluted either in liquid or gaseous material. After dilution, they are disposed off in sewer without causing hazard.

3. Sea Disposal- This dilution can be used by adequately diluting the wastes and this method is being used by the British.

4. Atmospheric Dilution- This method can be used for gaseous radioactive wastes. But solid particles from the gaseous wastes must be filtered out thoroughly since they are the most dangerous with higher half-lives.

5. Absorption by the Soil- Fission products are disposed off by this method. The radioactive particles are absorbed by the soil particles. But this is expensive.

6. Burying in Sea- Solid nuclear wastes can be stored is concrete blocks which are buried in the sea. This method is expensive but no further care is needed.

Essay # 3. Pollution from Hydro-Electric Power Plants and Solar Power Generating Stations:

Hydro-electric and Solar Power Generation plants have no polluting effect on the environment. The hydro-electric project does not pollute the atmosphere at all, but it can be argued that the solar power stations in the long run may upset the balance in nature. To extend the argument to the logical end, imagine a very vast area of land is covered by solar collectors of different forms. Then the minimum required sun’s rays may not reach the earth’s surface.

This will certainly kill the vegetation on the earth and also the bacteria which are destroyed by sun’s rays may survive giving rise to new types of health problems. Further, the evaporation of water and consequent rains may change their cycles. Added to these, the average temperatures of the earth and ocean may change. This may result in new balances among the living creatures which cannot be easily predicted. Since we do not envisage such large scale coverage of earth’s surface in the near future, we can safely state that the solar energy power plants do not pollute the atmosphere.