Are you looking for an essay on ‘Thermoelectric Power Generator’? Find paragraphs, long and short essays on ‘Thermoelectric Power Generator’ especially written for school and college students.

Essay on Thermoelectric Power Generator

Essay Contents:

- Essay on the Construction and Working of Thermoelectric Power Generator

- Essay on the Theory of Thermoelectric Power Generator

- Essay on Thermoelectric Materials and their Selection

- Essay on the Advantages and Disadvantages of Thermoelectric Power Generator

- Essay on the Power Output and Efficiency of Thermoelectric Power Generator

Essay # 1. Construction and Working of Thermoelectric Power Generator:

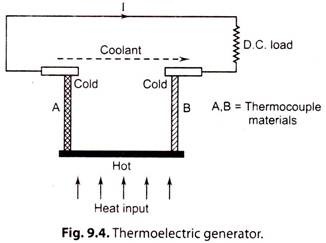

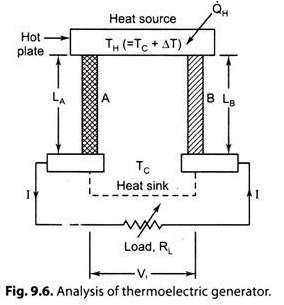

Fig. 9.4 shows a schematic diagram of a thermoelectric power generator. It uses seebeck effect to produce electrical energy directly from the available heat input. Its thermal efficiency is very low, of the order of 1 to 3%. In any heat engine the efficiency of thermoelectric generator depends upon the temperatures of hot and cold junctions.

The thermocouple materials A and B are joined at the hot end, but the other ends are kept cold; an electric voltage or electromotive force is then generated between the cold ends. A direct current (D.C.) will flow in a circuit or load connected between these ends.

The flow of current will continue as long as the heat is supplied to the hot junction and removed from the cold ends. For a given thermocouple, the voltage and electric power output are increased by increasing the temperature difference between the hot and cold ends.

Essay # 2. Theory of Thermoelectric Power Generator:

Consider a metal bar where one side is kept at a higher temperature than the other. If the free electrons in the metal are considered to behave as a gas, the kinetic theory of gases predicts that the free electrons in the hot side of the bar will be on higher kinetic energy and will be moving at greater speed than those in the cold side of the bar.

As the fast moving electrons flow from the hot side to the cold side of the bar, it results in an accumulation of negative charge at the cold side, preventing further build up until circuit is closed. In a closed circuit the current will flow to reduce the charge built up and will continue as long as the temperature is maintained.

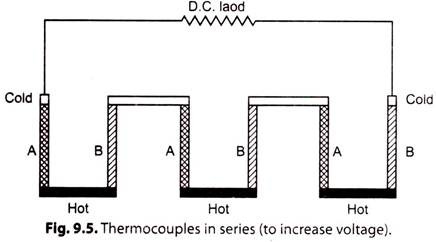

In a practical thermoelectric converter, several thermocouples are convicted in series to increase both voltage and power as shown in Fig. 9.5. If the output voltage is insufficient to operate a particular device or equipment, it can be increased, with little loss of power, by an inverter transformers combination.

The direct current generated by the thermocouples is first changed into alternating current (A.C.) of essentially the same average by means of an “inverter”. The alternating current and voltage is then increased to the desired value with the help of a transformer. The high voltage alternating current can be reconverted into direct current if required, by the use of a rectifier.

The source of heat for a thermoelectric generator may be a small oil or gas burner, a radioisotope or direct solar radiation.

A typical couple operating with hot and cold junction temperatures of 600°C and 200° C could be designed to give about 0.1 V and 2 A i.e., about 0.5 W, so that a 1kW device could require about 5000 couples in series.

i. Taking into account mechanical characteristics, stability under operating conditions and ease of fabrication, Bismuth telluride appears to be most suitable material. It can be alloyed with such materials as Bismuth selenide, Antimony telluride, lead selenide and tin telluride to give improved properties.

ii. Research is being carried out on the possibility of using thermoelectric devices within the core of a nuclear reactor. The hot junction would be located on the fuel element and the cold junctions in contact with the coolants.

Note:

A thermoelectric converter is a form of heat engine which takes up heat at an upper temperature (hot junction) converts it partly into electrical energy and discharges the remaining part at a lower temperature (cold junction).

The efficiency of a thermocouple, as is the case with other heat engines, increases by increasing the upper temperature and decreasing the lower temperature. Since the lower temperature is usually that of environment the efficiency of a thermocouple, practically, depends upon the hot junction temperature.

Essay # 3. Thermoelectric Materials and their Selection:

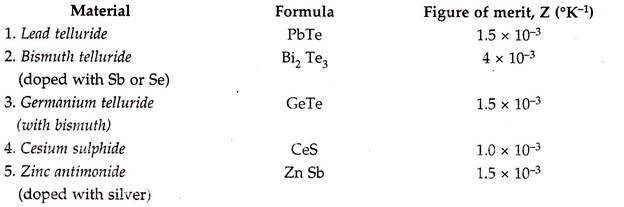

The following materials find use in the making of thermoelectric elements:

where Z is an index used in rating thermoelectric converters. It depends on the properties of thermoelectric materials used.

A high value of Z (Figure of merit) is obtained by using materials of:

(i) Large seebeck co-efficient

(ii) Small thermal conductivity

(iii) Small electrical resistivity.

i. In recent times, the most commonly used material for thermoelectric converters is lead telluride [a compound of lead and tellurim, containing small amounts of either bismuth (N-type)] or sodium (P-type)]. The efficiency of such a thermoelectric converter is, however, only about 5 to 7 per cent.

ii. Research is being made to find more efficient thermocouple materials. For ‘high temperature applications’, “semiconductors based on silicon-germanium and compounds of selenium” appear to be promising.

To achieve higher efficiency, thermoelectric material should have a high value of Z and be able to operate upto very high temperature.

The following points are worth noting in this regard:

1. The component thermal conductivity of semiconductor should be as low as possible.

2. The mobility of current carriers (electrons or holes, should be as high as is compatible with condition 1).

3. One of the arms should consist of a purely hole type and the other of a purely electronic type semiconductor.

4. In the low temperature zone the impurity concentration should be lower than in the higher temperature zone.

5. So that the thermoelectric material may not crack under the effect of stresses it should possess the following properties:

(i) It should be able to resist chemical influences such as oxidation etc.

(ii) It should have good mechanical strength.

(iii) It should be amply elastic.

Essay # 4. Advantages and Disadvantages of Thermoelectric Power Generator:

Following are the advantages and disadvantages of thermoelectric power generator.

Advantages of Thermoelectric Power Generator:

1. Highly reliable.

2. Free from noise due to the absence of parts.

3. Compact and durable.

4. Minimum maintenance.

5. Portable (can be used at any location).

6. Uses low grade thermal energy.

Disadvantages of Thermoelectric Power Generator:

1. Low output.

2. Low efficiency.

3. High cost.

Essay # 5. Power Output and Efficiency of Thermoelectric Power Generator:

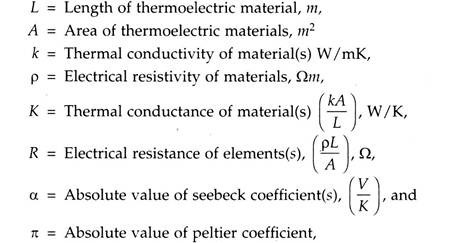

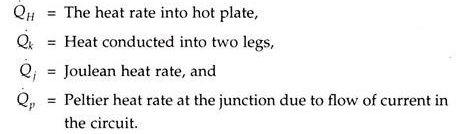

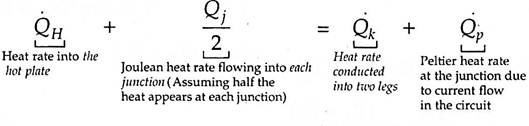

Refer to Fig. 9.6.

Let, T1 = Temperature of the source, K

T0 = Temperature of the sink, K,

Consider hot plate at control volume.

The seebeck voltage (V) generated as a result of current flow I in the circuit when the load Rl is placed in the circuit is given by:

V = αAB.(TH-Tc) …(9.9)

According to first law of thermodynamics, the energy balance equation can be written as: