This article throws light upon the top three ways to reduce railway noise. The ways are: 1. Use of Noise Barriers 2. Rubber-Tyred Wheels 3. Underground Railways.

Reduce Railway Noise: Way # 1. Use of Noise Barriers:

In principle, the surroundings adjacent to a particular stretch of railway tracks could be quietened by erecting a noise barrier alongside the tracks The effectiveness of such a barrier within its shadow zone is not heavily dependent on the distance between the tracks and barrier.

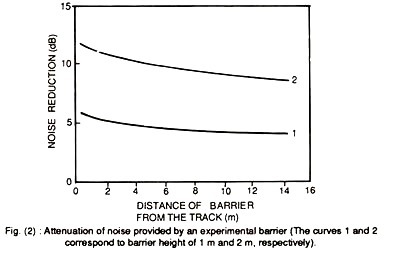

On the other hand, this distance obviously affects strongly the size of the shadow zone for a given barrier height It has been found that, for a barrier at a particular distance from the tracks, reduction in noise level in the shadow zone is directly proportional to the height of the barrier The attenuation of train noise by an experimental barrier as a function of its height and distance from the tracks is shown in Fig. 2.

Noise barrier, however, is not a very practical solution for rail ways. In the first place, it is very expensive. Secondly, it has to be very long, even when protection of a very small site is considered.

This follows from the fact that the length of typical trains may be about 250 metres and the barrier must be longer than that. Thirdly, the barrier presents a serious hazard to men working on the track, hinders access to it and also requires maintenance.

Reduce Railway Noise: Way # 2. Rubber-Tyred Wheels:

The concept or use of rubber-tyred wheels in railway trains is not new. The first commercial prototype of a railway coach having rubber-tyred wheels was produced by Michelin in 1931. It ran the 220 km stretch from Paris to Deauville at an average speed of 107 km/h.

Higher speeds up to 130 km/h were achieved with later designs. These coaches had 24 pneumatic tyres with high-tensile steel cords profiled to run on standard railway lines. There were 94 such coaches running on the French railways by 1937.

Michelin introduced a completely rubber-tyred train in 1948. Eventually, three of such trains ran on the Paris-Strasbourg route. But the design of these rubber-tyred trains was not pursued further.

The reason was that quietness inside railway carnages was more readily achieved by the introduction of welded track. The main limitation of rubber-tyred wheels, however, was that pneumatic tyres had to be operated on the top of a very narrow track and this prevented the tyres from being used to their maximum capacity.

Michelin developed a system using ordinary tyres to carry the load on ordinary concrete tracks to overcome the difficulty mentioned above. This system had also steel wheels and rails to ensure against tyre failure and to provide guidance, especially through crossings. This system was used on a trial basis on the Paris Metro in 1951 and was extended to a complete route in 1957.

In this system, the coaches had four load-bearing tyres running on a concrete track, outside the normal permanent steel way, plus four smaller tyres acting upon the outside of the steel track to provide guidance. This system has proved to be highly successful and has been introduced also in the Metro systems in Montreal and Mexico City.

Reduce Railway Noise: Way # 3. Underground Railways:

Excessive noise and vibrations are likely to be caused by underground railways in nearby buildings. This is true especially for cut-and-cover lines which may run at basement level. In order to reduce the noise level in underground railways, metal-to-metal contact may be eliminated by using rubber-tyred wheels.

Other alternatives, apart from this, are to mount the buildings likely to be affected on resilient mountings or place the railway itself on resilient mountings. These two alternative systems are almost similar from the point of view of construction costs. Resilient mounting as a solution to the problem of excessive noise, however, is applicable only in the case of new constructions and not the existing railway systems.

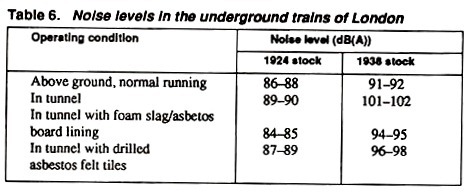

The noise levels in the underground trains of London are given in Table 6. These noise levels were recorded in coaches with windows open. In the case of entries in the last two rows of this table, the lining or tiles in the tunnels concerned were up to the level of coach floor. Several interesting things can be noted from Table 6.

In the first place, the coaches of 1938 stock are noisier than those belonging to the 1924 stock, in all cases without exception. This is probably due to increased train speeds for the 1938 stock.

Secondly, the coaches are noisier when the train is running in a tunnel than for its normal running above ground, and this is true for both 1924 and 1938 stocks. We note, finally, that foam slag/asbestos lining of the tunnel is more effective in reducing the level of passenger noise than drilled asbestos felt tiles.