After reading this article you will learn about Railway Noise:- 1. Subject Matter of Railway Noise 2. Sources of Railway Noise 3. Annoyance Caused 4. Air-borne Noise 5. Reduction 6. Breaking Mechanism 7. Passenger Noise 8. Future Developments.

Contents:

- Subject Matter of Railway Noise

- Sources of Railway Noise

- Annoyance Caused by Railway Noise

- Air-borne Noise

- Reduction of Railway Noise

- Breaking Mechanism Causes Railway Noise

- Passenger Noise

- Future Developments in Railways

1. Subject Matter of Railway Noise:

Railway noise, in general, may not seem to be a subject of widespread public annoyance the exception being the inhabitants in the immediate vicinity of railway lines. People who are most affected by railway noise are those occupying houses close to railway lines, busy stations and shunting yards.

In the majority of cases, however, the buildings in the vicinity of railway systems are constructed sufficiency far from the noise sources. Consequently, the actual noise level reaching such buddings is low enough to be acceptable.

In fact, it may be lower than that from other major noise sources, e.g., traffic noise. In these cases, a relevant fact of particular significance is that wind can play an important part in determining the level of railway noise actually reaching a distant building. As a corollary, the optimum siting of buildings near railway systems should take into account the prevailing wind direction in the concerned regions.

2. Sources of Railway Noise:

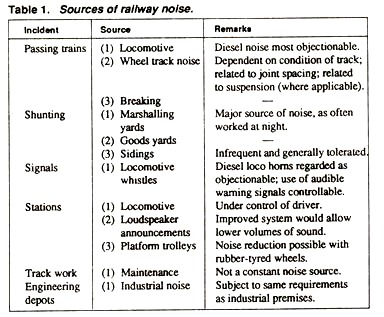

Sources of rad way noise are summarised in Table 1. In addition to noise, there are vibrations and these too can be a source of annoyance and objection. Fast trains operating in urban areas pose special problems. In Japan, for example, high speed trains have created considerable amounts of stress for the inhabitants along the railway lines.

For these trains, the noise exceeds the peak level of 85 dB (A) at 25 metres distance from the centre line of the tracks. In certain stretches of the tracks of such fast trains, however, the noise level reaches between 90 and 100 dB(A) at a distance of 25 metres from the tracks.

Railway system consists of three components, viz., train, track and road bed. The rolling device (wheels and rail) is the main source of noise in this system. Other important sources of noise are body vibrations of the train and vibrations of the structure on the ground such as the road-bed.

Other sources of noise, e.g., driving gear, current collecting device (in the case of electric locomotives) and other supplementary installations, are much less important and other no problems. There are several factors which have a great influence on noise exposure.

Some of these are: formation of a train, its speed and the frequency of running at different times of the day. Of particular interest among these is the speed of the train, since noise power (sound energy received per unit area per unit time) increases as the square of train speed as a general rule.

Noise exposure might also be influenced by the existence of a noise insulation wall, its structure, distance from tracks, distribution of buildings along the tracks, geographical surroundings and atmospheric conditions.

3. Annoyance Caused by Railway Noise:

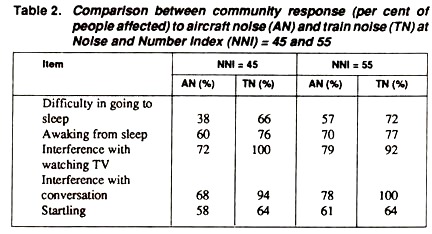

Another significant point to remember in this connection is that train noise may prove to be subjectively more disturbing than aircraft noise for the same level of noise exposure. The level of noise exposure is a function of peak noise level and the number of incidents.

It is expressed usually by the “Noise and Number Index” (NNI). Response of community to aircraft noise (AN) and train noise (TN) at the same values of noise and number index (NNI = 45 and 55), as determined by one survey, is shown in Table 2. We find from this table that at both values of NNI and for all items studied by this survey, more people are disturbed by train noise than by aircraft noise.

4. Air-borne Noise:

The main sources of air-borne noise are the locomotive and the wheel-track combination. The intensity of the air-borne train noise, as expected, is also dependent on the train speed.

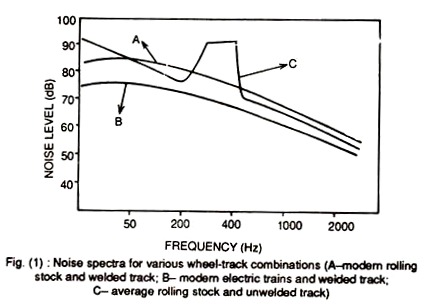

Study of noise spectra (noise level as a function of frequency) has shown that at a particular distance from the tracks, the level of airborne train noise decreases with the frequency of sound. This decrease in noise level is almost linear and it is quite typical for most forms of passenger trains running at moderate speeds.

On the other hand, if the track is in poor condition, the noise spectrum may exhibit a definite peak, usually in the 300-600 Hz frequency range. Even when tracks are in good condition, a peak may develop in the noise spectrum, in a similar frequency range, at higher speeds.

Such peaks may be significant, since the reduction in sound pressure level with distance from the tracks is not necessarily the same for all frequencies. The noise spectra for the two cases are shown in Fig. 1.

Measurements have shown that the peak wheel-track noise level due to passage of trains increases linearly with the train speed. Noise power, however, which is proportional to the square of sound pressure level, increases in proportion to the square of train speed.

Similarly, the peak wheel-track noise level decreases linearly with the distance from the tracks and this rule gives a fair degree of approximation to the attenuation of air-borne train noise in still air.

The best method of reducing the train noise affecting the buildings near the railway lines is to erect sound barriers near the tracks. But this is quite expensive and when it is not feasible, distance is the only factor under the control of a person constructing buildings in the vicinity of a railway line.

5. Reduction of Railway Noise:

Let us consider first the reduction of sound at the source. There are many factors to be considered for reducing track-generated train noise. These include the use of long lengths of welded track to avoid gaps, the choice of rail materials which do not develop uneven wear or corrugations to promote wheel vibrations and attention to weights without springs, since these directly affect the degree of wheel vibrations.

Of course, the wheels are not the only source of vibrations; the rails themselves are also excited into vibration. Experience has shown, however, that the vibrations of rails are not very significant except on overhead systems where the rails may be carried on rigid steel structures which can become a secondary source of vibration.

The attempts made so far to reduce train noise at source have generally been aimed at reducing the noise level affecting the passengers rather than the external air-borne noise. Any gains in the reduction of air-borne train noise are, therefore, largely incidental.

The methods which have high potential for reducing external noise level include:

(1) The use of rubber-tyred wheels,

(2) Rubber isolation of the tracks, and

(3) The use of semi-flexible skirt enclosures on rolling stock.

The first two of these methods are aimed at reducing the wheel-track noise level. The last method, on the other hand, follows from the fact that the majority of noise is generated on the underbody of the rolling stock. It follows, therefore, that the radiation of this noise can be reduced by enclosure.

6. Breaking Mechanism Causes Railway Noise:

The most obvious factor to affect the noise level of a running train is the choice of breaking mechanism. Iron blocks clamping onto the running tread of the wheel have been employed traditionally to serve the purpose of railway brakes.

In recent years, however, disc brakes have also been introduced for this purpose In this case, there may be a separate brake disc mounted on the wheel set axle or there may be brake disc cheeks fitted on either side of the webs of the running wheels.

The effect of disc brakes on the reduction of wayside train noise is spectacular Disc brakes may reduce the noise level by 10 dB (A) or more. In addition to this they improve also the spectra characteristics of the noise by reducing its high-frequency component.

Quiet running of fast trains arising from the use of disc brakes has been observed in several countries, including the U.K., Germany, Spain and Japan The reasons for this relative quietness still remain obscure; but the most probable reason appears to be that, when disc brakes are used, mechanical and/or metallurgical damage to the running surface of the wheel is less severe.

7. Passenger Noise:

Noise inside train compartments or “passenger noise” is largely due to the vibrations produced by the rolling stock wheels on the rails. Locomotive noise is not very important inside the compartments as it is unlikely to be transmitted back through the rolling stock, although air-borne locomotive noise may be introduced through open windows and doors.

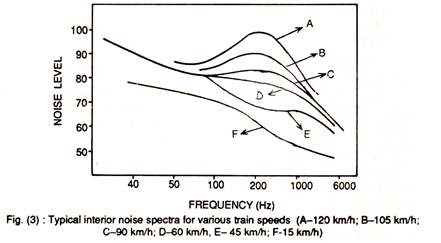

Thus the primary source of passenger noise is the noise generated under the passenger carriage and this increases appreciably with speed. Typical interior noise spectra for various train speeds are shown in Fig. 3, where frequency is plotted on a logarithmic scale.

Wheel-track noise may be transmitted directly to the structure of the carriage. Air-borne noise, on the other hand, usually strikes the underside of the floor – and to a lesser extent its sides – and is transmitted through the floor of the structure, and directly to the interior through holes in the floor.

The noise level inside the railway carriage is dependent, therefore, on the efficacy of damping of transmitted vibrations and attenuation of air-borne sound by insulation. The noise level inside the carriage varies also with the position of the passenger within it.

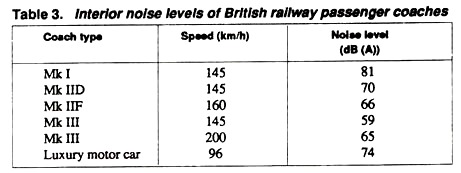

Improvements in the construction of railway carriages in the second half of this century have resulted in coaches which have become successively quieter for the passengers. Since no data on the passenger noise are available in literature for Indian railways, some typical data for the passenger coaches of British railways are reproduced in Table 3.

In this Table, the types of carriage are given in historical order. For example, Mk I is the earliest type, while Mk III is the latest one. For comparison, the noise level inside a modern luxury motor car is given at the bottom of this table.

Table 3 clearly shows the progress that has been made by the exploitation of good acoustic design. The figures given in this table refer to the centre of a second- class open coach of a train running in open country over continuously welded rail.

We note from this table that the interior of railway carriages has become progressively quiter in recent years. Of particular interest is the last entry (noise level inside a luxury car). It clearly illustrates the fact high speed trains, running at twice the quoted speed of the car, produce an internal noise background only half as loud.

8. Future Developments in Railways:

It is worthwhile to consider the ways in which noise enters a railway carriage in order to appreciate better the progress which has already been made and the problems which are yet to be solved. For the present discussion, we may ignore air conditioning and ancillary noise, which is negligible when the train is running. Leaving aside this, there are three principal routes by which noise enters the coach.

In the first place, the wheel-track noise serves as a powerful input to the coach. The coach structure must provide an adequate transmission loss to reduce this noise. The wheel-track noise reaching the coach is obviously stronger on the underside and lower side walls than it is elsewhere. These parts of the coach, therefore, have to be designed more carefully.

The second route to coach noise is provided by the vehicle suspension. In this case, the vibrations generated at the wheel-track interface enter the body of the coach through the vehicle suspension. These vibrations diffuse through the structure and cause the internal panels to vibrate and radiate noise.

Lastly, a train running at high speed through the air causes a turbulent boundary layer. The eddies of this layer beat on the body panels of the coach and excite vibrations. The noise arising through this mechanism is essentially a low-frequency noise over most of the train length. Its significance, however, rises rapidly as the train speed increases above 100 km/h.

The main factor which has contributed to the reduction of passenger noise in Britain and other advanced countries is the introduction of air conditioning. This makes the opening of windows unnecessary, thus avoiding the attendant inevitable acoustic leaks. At the same time, the rest of the structure of railway carriages has been improved.

For example, it has been possible to provide resilience in the floor mounting. Noise-absorbent materials have been used inside the coaches to the greatest extent possible. All of these measures, as it turns out, are more effective at higher frequencies than at lower ones.

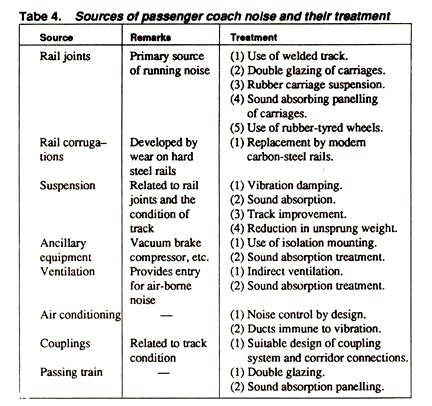

The noise spectrum has therefore altered radically as the carriages have become quieter. The sources of passenger noise and their treatments are given in Table 4.

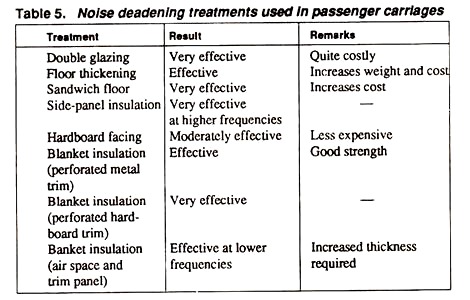

It is a widely acknowledged fact now that, at least in advanced countries, the noise level inside railway carriages has reduced considerably. Let us consider now the problems for future solution. The improvements so far have been achieved mainly by the acoustic damping treatments given in Table 5 and condensable amounts of mass have been assigned just for this purpose.

But some changes in the philosophy of design are needed when we go for superfast trains. In the concept of high-speed light-weight trains, there is no scope for the application of excess mass for the purpose of acoustic damping.

For example, it is necessary to ensure that the audio-frequency transmissibility of the carriage suspension is as low as possible. When this is the case, damping treatments need only be local and selective.

Analytical techniques have already been developed to determine the balance between different inputs to interior noise. Analysis of Mk III coach (developed in Britain) shows, for example, that the windows contribute most of the sound energy arising from the external noise field. The windows of these coaches are factory- sealed double glazed units, having two panels of equal thickness, separated by a thin film of air.

This design turns out to be less effective acoustically, for the purpose of noise insulation, than a single glass pane of the same weight. But the single pane, on the other hand, would be undesirable thermally.

This dilemma has been resolved to some extent by constructing the windows as factory-sealed units having panes of unequal thickness and as great a separation as possible, consistent with other constraints in the design.