Here is my favourite essay on ‘Wind Energy’? Find paragraphs, long and short essays on ‘Wind Energy’ especially written for school and college students.

Essay on Wind Energy

Essay Contents:

- Essay on the Introduction to Wind Energy

- Essay on the Utilisation Aspects of Wind Energy

- Essay on the Environmental Impacts of Wind Energy

- Essay on Wind Availability and Measurement

- Essay on Wind Energy Pattern Factor (EPF)

- Essay on the Extraction of Wind Energy

- Essay on the Classification and Description of Wind Mills/Machines

- Essay on the Variation of Power Output with Wind Speed

- Essay on the Analysis of Aerodynamic Forces on a Blade

- Essay on Wind-Electric Generating Power Plant

- Essay on Electric Generating Systems of Wind Turbine

- Essay on Wind-Powered Battery Chargers

- Essay on Wind Electricity in Small Independent Grids

- Essay on the Advantages and Disadvantages of Wind Energy

Essay # 1. Introduction to Wind Energy:

Wind is air set in motion by small amount of insolation reaching the upper atmosphere of earth. It contains kinetic energy (K.E.) which can easily be converted to electrical energy. Nature generates about 1.67 x 105 kWh of wind energy annually over land area of earth and 10 times this figure over the entire globe.

i. This wind energy, which is an indirect source of energy, can be used to run a wind mill which in turn drives a generator to produce electricity.

ii. Although wind mills have been used for more than a dozen centuries for grinding grain and pumping water, interest in large scale power generation has developed over the past 50 years. A largest wind generator built in the past was 800 kW unit operated in France from 1958-60. The flexible 3 blades propeller was about 35 m in diameter and produced the rated power in a 60 km/hour wind with a rotation speed of 47 r.p.m.

iii. In India the interest in the wind mills was shown in the last fifties and early sixties. Apart from importing a few from outside, new designs were also developed, but these were not sustained. It is only in last 20-25 years that development work is going on in many institutions.

An important reason for this lack of interest in wind energy must be that wind, in India is relatively low and vary appreciably with seasons. These low and seasonal winds imply a high cost of exploitation of wind energy. In our country high wind speeds are however available in coastal areas of Sourashtra, Western Rajasthan and some parts of central India. In these areas there could be a possibility of using medium and large sized wind mills for generation of electricity.

Essay # 2. Utilisation Aspects of Wind Energy:

Utilisation aspects of wind energy fall into the following three broad categories:

1. Isolated continuous duty systems which need suitable energy storage and reconversion systems.

2. Fuel-supplement systems in conjunction with power grid or isolated conventional generating units.

This utilisation aspect of wind energy is the most predominant in use as it saves fuel and is fast growing particularly in energy deficient grids.

3. Small rural systems which can use energy when wind is available.

This category has application in developing countries with large isolated rural areas.

Essay # 3. Environmental Impacts of Wind Energy:

The possible environmental impacts of wind energy are:

1. Wind energy creates noise pollution because of mechanical (gear box) aerodynamic noise.

2. The wind turbine produces electromagnetic interference when placed between radio, television etc. stations, as it reflects some electromagnetic radiations.

3. It produces visual shining because of reflection and refraction which depends upon turbine size, number of turbines in wind farm, design etc.

4. Safety consideration for life because of accidental braking of blade.

5. Fatal collisions of birds caused by rotating turbine blades.

Essay # 4. Wind Availability and Measurement:

Wind energy can only be economical in areas of good wind availability. Wind energy differs with region and season and also, possibly to an even greater degree with local terrain and vegetation. Although wind speeds generally increases with height, varying speeds are found over different kinds of terrain.

Observations of wind speed are carried out at meteorological stations, airports and lighthouses and are recorded regularly with ten minute mean values being taken every three hours at a height of 10 m. But airports sometimes are in valleys and many wind speed meters are situated low and combinations of various other factors mean that reading can be misleading. It is difficult, therefore, to determine the real wind speed of a certain place without actual in-situ measurements.

The World Meteorological Organisation (WMO) has accepted the following four methods of wind recording:

(i) Human observation and log book.

(ii) Mechanical cup-counter anemometers.

(iii) Data logger.

(iv) Continuous record of velocity and direction.

1. Human Observation and Log Book:

This involves using the Beaufort Scale of wind strengths which defines visible “symptoms” attributable to different wind speeds. The method is cheap and easily implemented but is often unreliable. The best that can be said of such records is that they are better than nothing.

2. Mechanical Cup-Counter Anemometers:

The majority of meteorological stations use mechanical cup-counter anemometers. By taking the readings twice or three times a day, it is possible to estimate the mean wind speed. This is a low cost method, but is only relatively reliable. The instrument has to be in good working order; it has to be correctly sited and should be reliably read atleast daily.

3. Data Logger:

The equipment summarizes velocity frequency and direction. It is more expensive and prone to technical failures but gives accurate data. The method is tailored to the production of readily interpretable data of relevance to wind energy assessment. It does not keep a time series record but presents the data in processed form.

4. Continuous Record of Velocity and Direction:

This is how data is recorded at major airports of permanently manned meteorological stations. The equipment is expensive and technically complex, but it retains a detailed times-series record (second-by-second) of wind direction and wind speed. Results are given in copious quantities of data which require lengthy and expensive analysis.

Variation of Wind Speed with Elevation:

The speed of wind increases with height above ground. Increase in wind speed with height above ground level is called wind shear. The wind speed at the ground is zero due to the friction between the ground surface and the air. Increase in wind speed with height is due to temperature gradient and it depends on the type of terrain over which the wind has travelled and atmospheric stability.

The change in wind speed with height, based on the data from several locations, for sites of low ground roughness, can be expressed as:

where Uω1, and Uω2 are wind speeds at levels H, and H2 respectively. This is known as power law index “α” which depends on the roughness of terrain. Its value is taken as 1/7 for open land and 0.10 for calm sea area.

The value of power index for a particular site is obtained from the measured wind at two heights by the following relation:

i. The ideal wind energy have a low value of α.

ii. Normally, wind measurements are carried out an elevation of 10 m. However, modern wind turbines are installed at a winds height of 25 to 50 m.

iii. Wind speed at the required height is calculated from Eqn. (5.1) with α = 1/7.

Essay # 5. Wind Energy Pattern Factor (EPF):

The energy pattern factor (EPF) is the ratio of power from speed distribution to the power from coverage speed of the turbine blades.

Generally, EPF lies between 2 to 5.

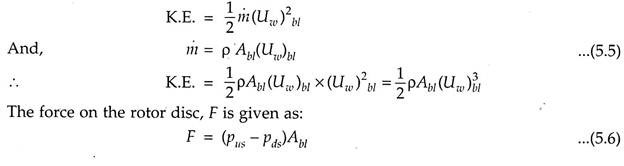

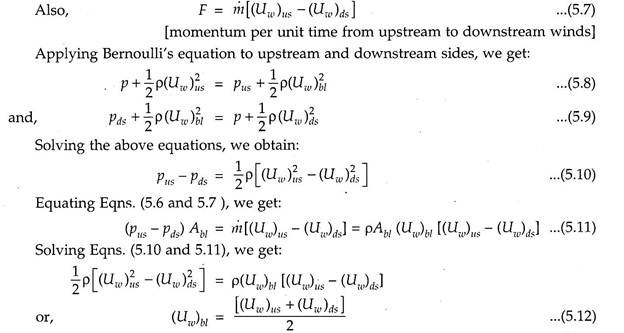

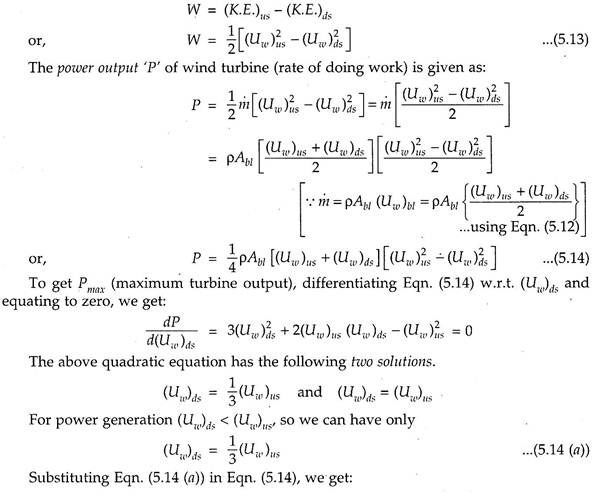

Essay # 6. Extraction of Wind Energy:

Energy from wind stream is extracted by a wind turbine, by converting the kinetic energy (K.E.) of the wind to rotational motion required to operate an electric generate.

In order to compute the mathematical relationships, let us make the following assumptions:

1. The flow of wind is ‘incompressible’, and hence the air stream diverges as it passes through the turbines

2. The mass flow rate of wind is ‘constant’ at far upstream, at the rotor and at far down stream.

Let, p = Atmospheric wind pressure,

pus = Pressure on upstream of wind turbine,

pds = Pressure on downstream of wind turbine,

Uω = Atmospheric wind velocity,

(Uω )us – Velocity of wind upstream of wind turbine,

(Uω )bl = Velocity of wind at blades,

(Uω )ds = Velocity of wind downstream of wind turbine before the wind front reforms and regains the atmospheric level,

Abl = Area of blades,

m = Mass flow rate of wind, and

p = Density of air.

The kinetic energy of wind stream passing through the turbine rotor is given by:

In a wind turbine system “Speed flow work”, W, is equal to the difference in kinetic energy between upstream and downstream of turbine for unit mass flow, in = 1. Therefore,

Essay # 7. Classification and Description of Wind Mills/Machines:

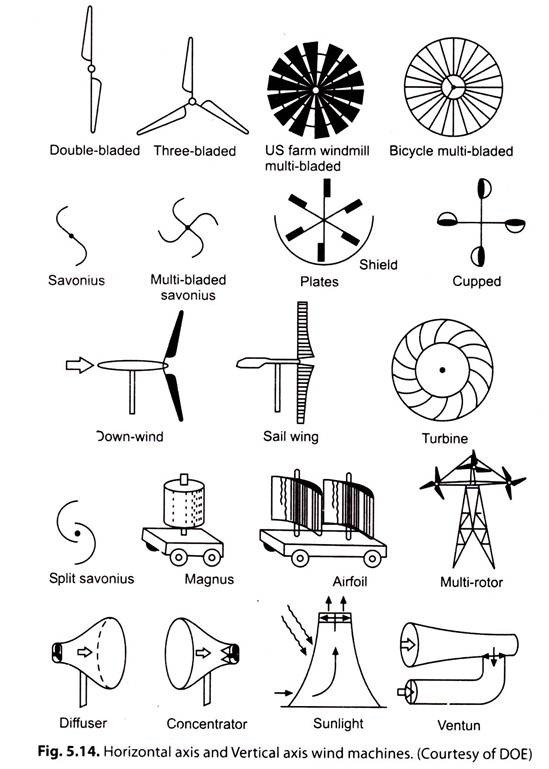

Classification of Wind Mills/Machines:

The wind mills machines are classified as follows:

1. Based on the Type of Rotor:

(i) Propeller type (horizontal axis)

(ii) Multiblade type (horizontal axis)

(iii) Savonius type (vertical axis)

(iv) Darrieus type (vertical axis).

2. Based on Orientation of the Axis of Rotor:

(i) Horizontal axis

(ii) Vertical axis.

Description of Wind Mills/Machines:

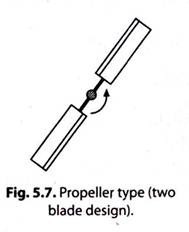

1. Propeller Type Wind Mill: (Refer to Fig. 5.7)

These are most commonly used wind mills. Such a wind mill has two or three blades for economical reasons. Though the two blade design is most efficient, yet it faces the difficulty of vibrations during orientation to wind direction called ‘Yaw control’. These machines are rated from 1 to 3 MW.

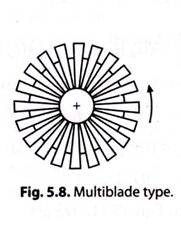

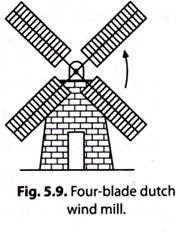

2. Multiblade Type Wind Mill: (Refer to Figs. 5.8 and 5.9)

The multiblade wind turbines are high solidity turbines used for pimping the water because of high starting torque characteristics.

The multiblade rotors are less efficient because of interference of blades in each other but they are less noisy.

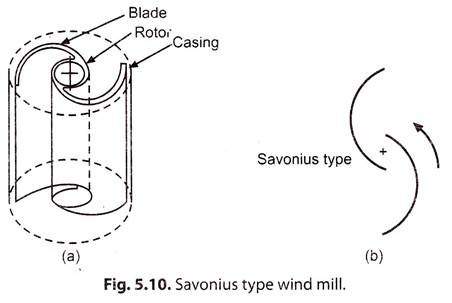

3. Savonius Type Wind Mill: (Refer to Fig. 5.10)

This type of wind mill has hallow circular cylinder sliced in half and the halves are mounted on vertical shaft with a gap in between. Torque is produced by pressure difference between the two sides of the half facing the wind.

This is quite efficience but needs a large surface area.

Advantages:

a. Low cost.

b. Operation at low wind velocity.

c. No need of yaw and pitch control.

d. Generator can be mounted at the ground level.

Applications:

It is useful for grinding grains, pumping etc.

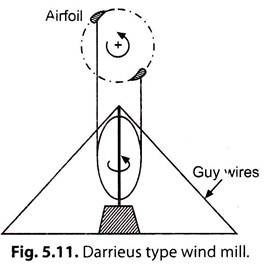

4. Darrieus Type Wind Mill: (Refer to Fig. 5.11)

i. This wind mill needs much less surface area.

ii. It is shaped like an egg beater and has two or three blades shaped like airfoils.

Characteristics of Darrieus Rotor:

(i) Not self-starting, needs auxiliary starter.

(ii) High speed.

(iii) High efficiency.

(iv) Potentially low capital cost.

Advantages:

(i) The generator, gear box etc. are placed on the ground.

(ii) No need of yaw mechanism to turn the motor against the wind. It may be noted that:

a. Both the Savonius and Darrieus types are mounted on a vertical axis and hence they can run independently of the direction of wind.

b. The horizontal axis mills have to face the direction of the wind in order to generate power.

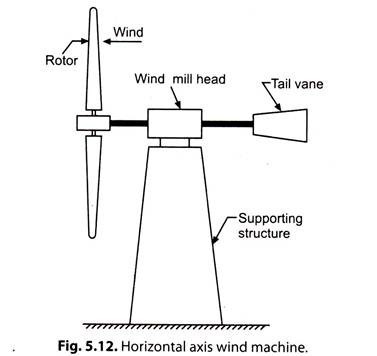

5. Horizontal Axis Wind Machines:

Fig. 5.12 shows a schematic arrangement of a horizontal axis machine.

i. Although the common wind turbine with a horizontal axis is simple in principle, yet the design of a complete system, especially a large one that would produce electric power economically, is complex.

ii. It is of paramount importance that the components like rotor, transmission, generator and tower should not only be as efficient as possible but they must also function effectively in combination.

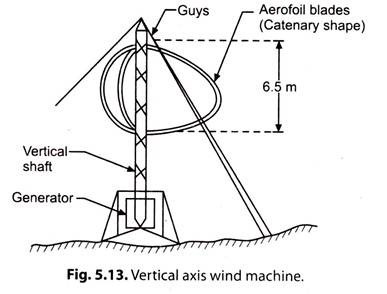

6. Vertical Axis Wind Machines:

Fig. 5.13 shows vertical axis type wind machine.

One of the main advantages of vertical axis rotors is that they do not have to be turned into the wind-stream as the wind direction changes, because their operation is independent of wind direction. These vertical axis machines are called panemones.

Advantages of Vertical Axis Wind Machines:

1. The rotor is not subjected to continuous cyclic gravity loads since the blades do not turn end over end (Fatigue induced by such action is a major consideration in the design of large horizontal axis machines).

2. Since these machines would react to wind from any direction, therefore, they do not need yawing equipment to turn the rotor into the wind.

3. As heavy components (e.g. gear box, generator) can be located at ground level these machines may need less structural support.

4. The installation and maintenance are easy in this type of configuration.

Fig. 5.14 shows horizontal axis and vertical axis wind machines.

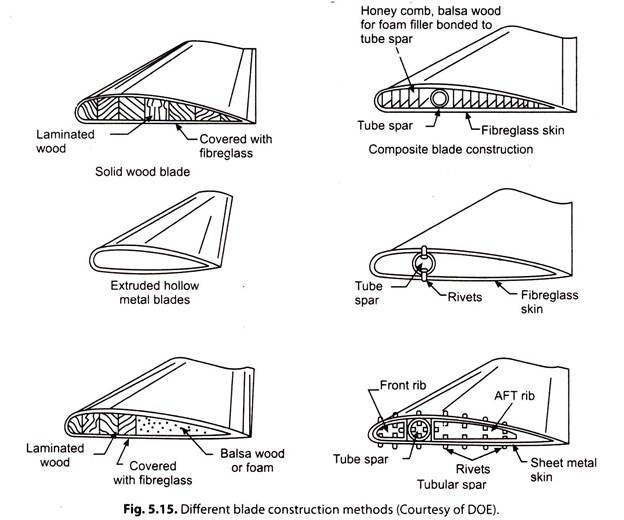

Blade Construction Methods:

The major construction variations one finds while selecting a ‘Wind energy conversion system (WECS)’ generally will involve the blade. One popular blade material is wood, either laminated 01 solid, with or without fibreglass coatings, as shown in Fig. 5.15.

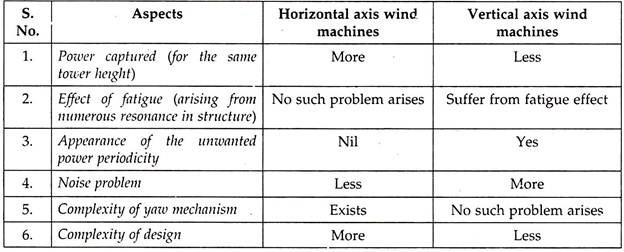

Comparison between Horizontal Axis and Vertical Machines:

Parameters to be Considered while Selecting a Wind Mill:

The following parameters should be considered while selecting a wind mill/wind generator:

1. Low land cost.

2. The area should be open and away from cities.

3. Flat open area should be selected, as the wind velocities are high in flat open area.

4. The proposed altitude is to selected by taking average wind speed data.

5. Minimum wind speed should be available throughout the year.

6. Ground surface should be stable and have high soil strength.

7. It should be atleast 5 km away from the cities to reduce the effect of sound pollution.

8. The wind power should be near the customers, so that the transmission losses are minimised.

9. Approach road should be available upto site.

Design Considerations for Wind Turbine:

The wind turbine must be able to meet the following design considerations/criteria:

1. It should be small in size and suitable for roof mounting in urban area.

2. No risk for its neighbourhood.

3. The efficiency should be good.

4. Insensitive to turbulence.

5. Suitable for mass production for low price.

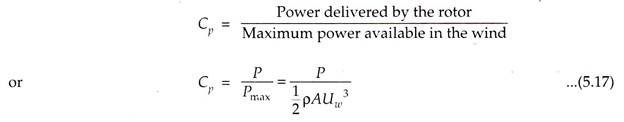

Performance of Wind Mills:

The performance of a wind mill is defined as ‘Co-efficient of performance'(Cp)

where, p = Density of air,

A = Swept area, and

Uω = Velocity of wind.

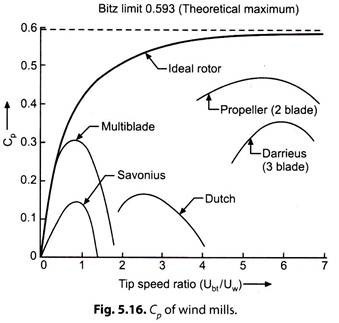

Fig. 5.16 shows a plot between Cp and tip speed ratio (TSR = Ubt/Uω)

where, Ubt = Speed of blade tip.

It can be seen that Cp is the lowest of Savonius and Dutch types whereas the propeller types have the highest value.

In the designing of wind mills, it is upper most to keep the power to weight ratio ‘at the lowest possible level.

The maximum theoretical coefficient of performance (Cp)is 0.593.

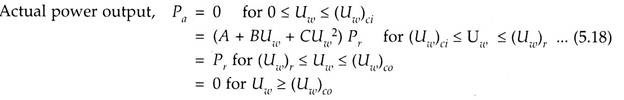

Essay # 8. Variation of Power Output with Wind Speed:

The actual power output of a wind turbine generator (WTG) system depends on the following wind speeds:

(i) Actual wind speed,

(ii) Rated wind speed,

(iii) Cut-in speed (i.e. speed at which system losses ‘equal’ the extracted wind power), and

(iv) Cut-out speed (i.e., speed at which the wind mill has to be ‘shut down for safety reasons).

The power can be approximated by the relation:

where, Uω = Actual wind speed,

Pr = Rated power output,

(Uω)ci = Cut-in speed,

(Uω)r = Rated wind speed, and

(Uω)co = Cut-out wind speed.

A, B, C are functions of (Uω)ci and (Uω)r.

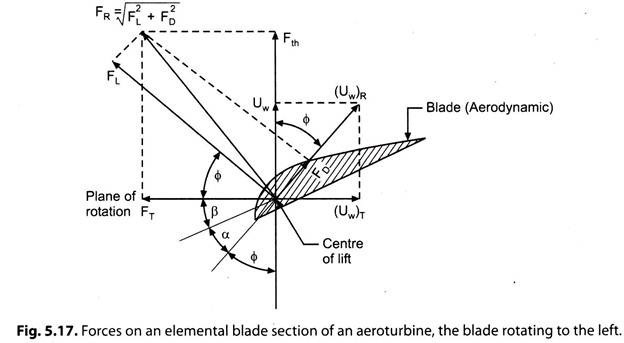

Essay # 9. Analysis of Aerodynamic Forces on a Blade:

Fig. 5.17 shows the vector diagram of forces on an elemental blade section of an aeroturbine, the blade rotating to the left. The blade is a typical cross-sectional element of a two-bladed aeroturbine. The element shown is at some radius V from the axis of rotation, and is moving to the left.

Refer to Fig. 5.11.

Uω = Wind velocity that impinges on the blade,

(Uω)T = Wind velocity in plane of rotation due to blade burning,

(Uω)R = Resultant wind velocity seen by Aeroturbine blade

FL = Lift force [Normal to (Uω)R],

FD = Drag force [Parallel to (Uω)R],

FR = Resultant force on the blade,

FT = Torque producing component of FR making aeroturbine rotate,

Fth = Thrust force component of PR,

α = Angle of attack of the blade, and

P = Blade pitch angle.

i. (Uω)t when added vectorially to Uω gives (Uω)R, seen by the rotating blade element.

ii. FL caused by the aerodynamic shape of the blade is perpendicular to (Uω)R. FD is parallel to (Uω)R.

iii. The vector sum of FL and FD is FR which has a torque producing component FT and a thrust producing component Fth. The component FT drives the aeroturbine rotationally, while the component Fth tends to flex the blade and also overturn the aerogenerator.

iv. The angle of attack ‘α’ of the aerodynamic element determines lift and drag forces and hence speed and torque output of the aeroturbine. These quantities can be altered by changing the blade pitch angle ‘β’, and this is the basic torque control method used on large variable pitch ‘wind-electric generators’.

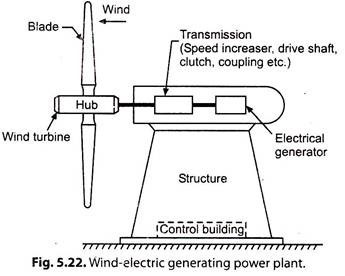

Essay # 10. Wind-Electric Generating Power Plant:

Fig. 5.22 shows the various parts of a wind-electric generating power plant.

These are:

1. Wind turbine or rotor.

2. Wind mill head-it houses speed increaser, drive shaft, clutch, coupling etc.

3. Electrical generator.

4. Supporting structure.

a. The most important component is the rotor. For an effective utilisation, all components should be properly designed and matched with the rest of the components.

b. The wind mill head performs the following functions:

(i) It supports the rotor housing and the rotor bearings.

(ii) It also houses any control mechanism incorporated like changing the pitch of the blades for safety devices and tail vane to orient the rotor to face the wind, the latter is facilitated by mounting it on the top of the supporting structure on suitable bearings.

c. The wind turbine may be located either unwind or downwind of the power. In the unwind location the wind encounters the turbine before reaching the tower. Downwind rotors are generally preferred especially for the large aerogenerators.

d. The supporting structure is designed to withstand the wind load during gusts. Its type and height is related to cost and transmission system incorporated. Horizontal axis wind turbines are mounted on towers so as to be above the level of turbulence and other ground related effects.

Applications of Wind Plants:

Following are the main applications of wind plants:

1. Electrical generation

2. Pumping

3. Drainage

4. Grinding grains

5. Saw milling

Essay # 11.

Electric Generating Systems of Wind Turbine:

The wind turbine-generator unit comprising wind turbine, gears and generator, converts wind power into electrical power. Several identical units are installed in a “Wind farm”. The total electrical power produced by the wind farm is fed into the distribution network or stand-alone electrical load.

The choice of electrical system for an aeroturbine is guided by three factors:

(i) Type of Electrical Output:

a. D.C.

b. Variable-frequency A.C.

c. Constant-frequency A.C.

(ii) Aeroturbine Rotational Speed:

a. Constant speed with variable blade pitch.

b. Nearly constant speed with simpler pitch-changing mechanism.

c. Variable speed with fixed pitch blades,

(iii) Utilisation of Electrical Energy Output:

a. In conjunction with battery or other form of storage.

b. Interconnection with power grid.

Constant Speed-Constant Frequency (CSCF) System:

Large scale electrical energy generated from wind is expected to be fed to the power grid to displace fuel generated kWh. For this application present economics and technological developments are heavily weighted in favour of CSCF system with alternator as the generating unit. It must be reminded here that to obtain high efficiencies the blade pitch varying mechanism and controls have to be installed.

Wind turbines of electrical rating of 100 kW and above are of constant-speed type and are coupled to synchronous generators (conventional type). The turbine rated at less than 100 kW is coupled to fairly constant speed induction generators connected to grid and so operating at constant frequency having their excitation VARs from the grid or capacitor compensators.

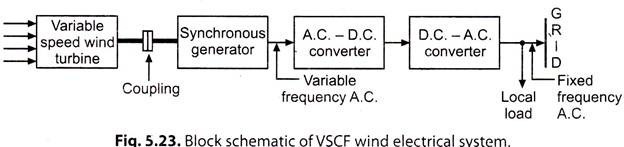

Variable Speed-Constant Frequency (VSCF) System:

Variable-speed drive is typical for small wind generators used in autonomous applications, generally producing variable frequency and variable voltage output.

The variable speed operation of wind electric system yields higher outputs for both low and high wind speeds. This results in higher annual energy yields per rated installed kW capacity. Both horizontal axis and vertical axis turbines will exhibit this gain under variable speed operation.

The following schemes are used to obtain constant frequency output:

(i) A.C.—D.C.—A.C. link

(ii) Double output induction generator.

(iii) A.C. commutation generator.

With the advent of power switching technology (viz., high power diodes and thyristors) and chip-based associated control circuitry, it has now become possible to use VSCF systems. VSCF and wind electrical systems and its associated power conditioning system operate as shown in Fig. 5.23.

VSCF wind electrical systems claim the following advantages:

1. Significant reduction in aerodynamic stresses, which are associated with constant- speed operation.

2. It is possible to extract extra energy in the high wind region of the speed-duration curve.

3. Complex pitch changing mechanism is not required.

4. Wind turbine/Aeroturbine always operates at maximum efficiency point (constant tip-speed ratio.)

Variable Speed-Variable Frequency (VSVF) System:

The generator output is affected by the variable speed. The frequency of the induced voltage depends on the impedance of the load and speed of the prime mover. The variable voltage can be converted to constant D.C. using choppers or rectifier and then to constant A.C. by the inverters.

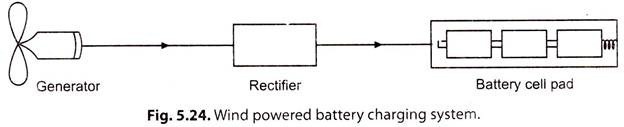

Essay # 12. Wind-Powered Battery Chargers:

One application of wind energy system which is of considerable potential importance (to developing countries) is the use of small wind generators to charge batteries for powering lighting, radio communication and hospital equipment. Wind generators have been in use in Europe and North America since the 1920s, although their use declined considerably.

A battery charging system has to include the following:

(i) A wind powered generator.

(ii) A converter.

(iii) A container for the batteries.

Fig. 5.24 shows a set-up of wind powered battery charging system. It is worth noting that 12 volt batteries, which are rechargeable using wind generators, can be used to power fluorescent tube lighting which is six times more efficient than tungsten filament lamps. Such lighting opens up a number of important development opportunities in areas which normally have no lighting.

For small wind generators the total system efficiency is made up as follows:

Wind regime matching efficiency 60% (approx.)

Rotor efficiency 35% (approx.)

Generator and wiring efficiency 70% (approx.)

Battery charge/discharge efficiency 70% (approx.)

Cumulatively, a total energy capture efficiency of about 10% is generally obtained from small wind generators utilized for battery charging.

Battery charging wind generators are produced in several countries, notably Australia, France, Sweden, Switzerland, the U.K., the U.S.A. and West Germany. In developing countries production is underway in China and has started in India.

Essay # 13. Wind Electricity in Small Independent Grids:

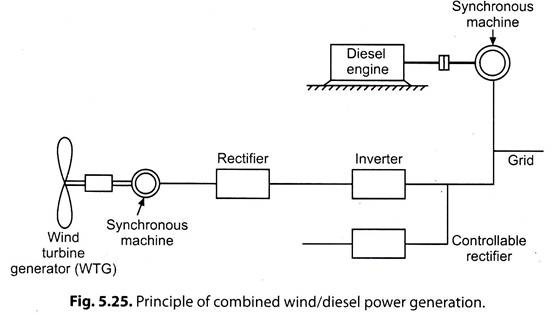

Refer to Fig. 5.25. In such systems electricity consumption fluctuates constantly as does the availability of wind energy. The degree of coincidence of supply and demand can be calculated by statistical means and it has been found that electricity supply with an acceptable degree of reliability cannot be based solely on wind energy.

If an extensive grid does not exist, electricity storages (batteries) or a back-up system (diesel) is required. Loads for remote systems of upto 6 kWh/day equivalent to an average power consumption of 250 W with a duty cycle of 24 hours, can be provided with battery storage.

Combined Wind/Diesel Power Generation:

A wind turbine generator (WTG) is very suitable for an isolated and remote area. To feed such an area from a power grid requires long transmission line and huge investment. Such areas are mostly served by diesel plants. If strong winds persist for sufficiently long periods, WTG system can be installed to work in combination with diesel plant.

For such an operation the following factors need consideration:

1. Gross output of WTG and power requirements of auxiliaries of WTG.

2. Change in diesel plant efficiency due to decrease in load.

3. Change in diesel plant efficiency due to the throttle activity.

The following operations need special attention:

(i) Start up and synchronisation of WTG with the diesel plant system, and

(ii) Normal shut down and cut-out of WTG.

Following are two ways, out of many ways, in which WTG can be used:

1. Isolated:

i. Wind electric supply

ii. Hybrid system

a. Wind-Diesel

b. Wind-Photovoltaic-Batteries

c. Wind-Photovoltaic-Diesel-Batteries

2. Grid connected.

Essay # 14. Advantages and Disadvantages of Wind Energy:

Following are the advantages and disadvantages of wind energy:

Advantages of Wind Energy:

1. It is a renewable energy source.

2. Wind power systems being non-polluting have no adverse effect on the environment.

3. Fuel provision and transport are not required in wind energy conversion systems.

4. Economically competitive.

5. Ideal choice for rural and remote areas and areas which lack other energy sources.

Disadvantages of Wind Energy:

1. Owing to its irregularity, the wind energy needs storage.

2. Availability of energy is fluctuating in nature.

3. The overall weight of a wind power system is relatively high.

4. Wind energy conversion systems are noisy in operation.

5. Large areas are required for installation/operation of wind energy systems.

6. Present systems are neither maintenance free, nor practically reliable.

7. Low energy density.

8. Favourable winds are available only in a few geographical locations, away from cities, forests.

9. Wind turbine design, manufacture and installation have proved to be most complex due to several variables and extreme stresses.

10. Requires energy storage batteries and/or stand by diesel generators for supply of continuous power to load.

11. Wind farms require flat, vacant land free from forests.

12. Only in kW and a few MW range; it does not meet the energy needs of large cities and industry.