Are you looking for an essay on the ‘Types of Geothermal Resources’? Find paragraphs, long and short essays on the ‘Types of Geothermal Resources’ especially written for school and college students.

Essay on Geothermal Resources

Essay Contents:

- Essay on Hydrothermal Resources

- Essay on Geopressured Resources

- Essay on Petro-Thermal Systems or Hot Dry Rocks (HDR) Resources

- Essay on Magma Resources (Molten-Rock-Chamber Systems)

- Essay on Hybrid Geothermal Fossil Systems

Essay # 1. Hydrothermal Resources:

In hydrothermal convective system water is heated by contact with hot rocks. These are wet reservoirs containing steam and hot water or only hot water. If the temperature is high enough then ‘steam’ generates electricity, otherwise ‘hot water’ is used for space heating and process heating. The water present in the porous medium is heated by convection process and convective heat flow occurs across hot rocks to water present in porous rock.

Examples of hydrothermal resource sites are:

(i) Landerello field in Italy;

(ii) Wairakei field in New Zealand;

(iii) Geyser geothermal field in California etc.

i. Vapour-Dominated or Dry Steam Fields:

The vapour-dominated reservoirs produce dry saturated steam of pressure above atmosphere and at high temperature about 350°C.

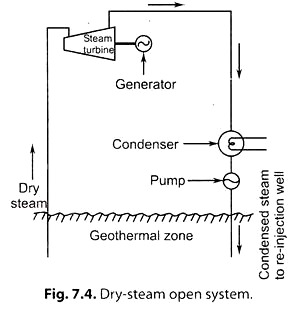

Fig. 7.4 shows a dry-steam open system.

i. Steam extracted from the well is cleaned in centrifugal separator which removes solid matters.

ii. The cleaned steam is then supplied directly into the ‘steam turbine’. The exhaust steam from steam turbine is wet steam, (i.e., mixture of water and steam) which passes through the condenser. The condenser condenses wet steam into water (through a cooling tower).

iii. The non-condensable gases present in wet steam are removed by ‘steam jet injection method’.

iv. The condensed steam is reinjected deep into the ground/well.

This system is used in Landerallo (Italy) and Geyser (USA).

Environmental Aspects:

i. The steam from hydrothermal resources may contain 0.5 to 5% by weight of non- condensable gas (mainly CO, CH4 and NH3) which are largely harmless in the quantities present. Gases also contain H2S (hydrogen sulphide) which is harmful to plant and animal life.

ii. The withdrawal of large amount of steam from the source may result in surface subsistence, mainly occurs in ‘oilfields’, is dealt with by injecting water into the ground. The re-injection of excess water is done at some distance from a ground fault.

ii. Liquid-Dominated Systems or Wet Steam Fields:

In such system water temperature is above the normal boiling point (100°C). Due to the pressure inside the reservoir, water does not boil but remains in liquid state. When the water comes on the earth surface its pressure reduces resulting in rapid boiling and the liquid water ‘flashes into a mixture of hot-water and steam’. The steam is separated from mixture and used to generate electricity.

(a) Liquid-Dominated High Temperature Systems:

For such systems, the following two methods are used:

(i) The flash steam open system.

(ii) The binary cycle system.

(i) The Flash Steam Open System:

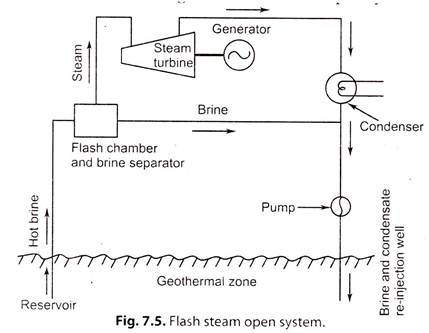

Fig. 7.5 shows a schematic diagram of flash steam open system.

Hot brine from the reservoir reaches the well head at lower pressure by throttling process. This low quality mixture is then throttled in flash separator which improves the quality of mixture. Now steam is separated as a dry saturated steam and supplied to the ‘steam turbine’, which produces electric power through a ‘generator’.

The ‘power generation’ from such system can be made more economical by associating chemical industry with power plant to make use of brine and gases effluent.

This system is used in Cerro Prietol Mexico, Otake (Japan).

Limitations:

Following are the limitations of flash steam open system as compared to vapour-dominated system:

1. Much larger total mass flow rates through the well required.

2. Owing to large amount of flows, there is a great degree of ground surface subsidence.

3. A greater degree of precipitation of minerals from the brine results in the necessity for design of valves, pumps, separator internals, and other equipment for operation under scaling conditions.

(ii) The Binary Cycle System:

The binary cycle concept isolates the steam turbine from corrosive or non-corrosive materials and/or to accommodate higher concentration of non-condensable gases.

This is basically a Rankine cycle with an organic working fluid.

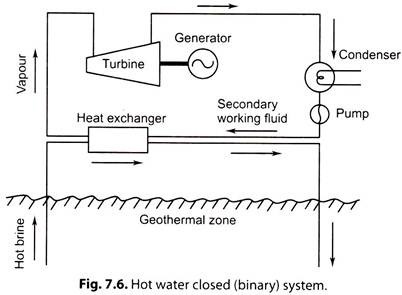

Fig. 7.6 illustrates a hot water closed (binary) system. ‘About 50 per cent of hydrothermal water is in the temperature range of 153°C to 205°C. In this system, a ‘heat exchanger’ is used to transfer a fraction of the brine enthalpy to vaporize the secondary working fluid. Expansion through a ‘turbine’ to a lower pressure is fixed by the heat rejection temperature which provides the means for power generation.

In this system there are no problems of corrosion or scaling in the working cycle components, such as the turbine and condenser. Such problems are confined only to the well casing and the heat exchanger. The ‘heat exchanger’ is a shell-and-tube type so that no contact between brine and working fluid takes place.

This system was first installed in the Soviet Union in 1967 on Kamchatka Peninsula having capacity of 680 kW. The firs binary cycle built in U.S.A. is of 11 MW capacity in California and second one at Raft-river-Idalio, is of a capacity of 10 MW.

Total Flow Concept System:

In such a system, both ‘kinetic energy’ and ‘heat energy of the steam-liquid mixture, produced by flashing the geothermal brine, are utilised. The overall efficiency for conversion into ‘eletrical energy’ should be greater than other methods in which only the heat content of the brine is utilised.

This system utilises the principle of the ‘Lysholm machine’, known in this connection as the helical (or screw) expander or mixed phase expander.

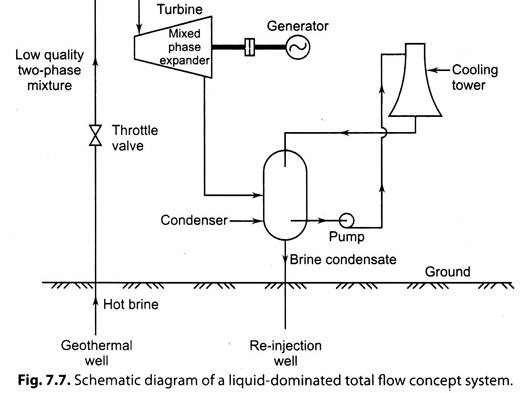

Fig. 7.7 shows the schematic diagram of a liquid-dominated total flow concept.

The hot brine from geothermal well is throttled where it becomes a two-phase mixture of low quality. The two phases at this point are not separated and the full flow is expanded in the ‘mixed phase expander’ (turbine) which is coupled with generator which generates electrical power. The mixture from the expander/turbine is discharged into condenser. Then the brine condensate is re-injected into the well.

Following are the requirements of mixed phase expanders:

(i) They should be able to overcome the losses associated with the impingement of liquid droplets on blades (the efficiency of the turbine decreases with the decrease in quality).

(ii) They must be able to withstand the corrosive and erosive effects of the significant quantities of dissolved solids in the brine.

(b) Liquid-Dominated Low Temperature Systems (Geothermal Fluids):

The hydrothermal reservoirs of this system are available at moderate temperature range of 90°C to 175°C.

Due to low temperature, little mineral water is extracted. If there is danger of corrosion then it can be passed through a heat exchanger to transfer heat from the natural hot water.

The main uses of this system include the following:

(i) To provide heat for homes, commercial and agricultural buildings including greenhouses and animal shelters.

(ii) Hot water may also be used for air-conditioning and refrigeration.

Essay # 2. Geopressured Resources:

The geopressured resources contain moderate temperature brines (160°C) containing dissolved methane. These are trapped under high pressure (nearly 1000 bar) in a deep sedimentary formation sealed between impermeable layers of shale and clay at depths of 2 to 10 km.

At geopressure, dissolved methane gas is usually 1.9-3.8 m per cubic metre of water. The methane gas is released from water on the earth surface because pressure at earth surface is lower. Therefore, methane gas is separated from brine by simple and economical gravity separation technique and burning of CH4 also produces energy.

When tapped by boring wells, three sources of energy are available:

(i) Thermal;

(ii) Mechanical-as pressure; and

(iii) Chemical-as methane.

The major resource area is along the Texas and Louisiana coast of the Gulf of Mexico which is about 1200 km in length. The potential of geopressured energy in this area is maximum 240 GW of electricity for 30 years.

Essay # 3. Petro-Thermal Systems or Hot Dry Rocks (HDR) Resources:

These systems are composed of hot dry rock (HDR) but no underground water. They represent by far the largest geothermal resources available.

The rock, occurring at moderate depths, has very low permeability and needs to be fractured to increase its heat transfer surface.

The recovery of heat from HDR involves drilling deep into hot rocks, then cracking it to form cavity or fractures.

This can be achieved by:

(i) Using high explosives at the bottom of the man-made well,

(ii) Using nuclear explosion, and

(iii) By hydraulic fracturing (pumping water at high pressure into the rock).

The thermal energy of the HDR is extracted by pumping water or fluid through a well at the lower part of the fractured rock and withdrawn by another well at a distance. The temperature of the rock at a depth of 5 km is about 200°C.

To achieve steady flow of high temperature water, the injection and extracting wells are joined to form a circulating loop. When heat is extracted through water, the rock cools down and due to temperature gradient between rocks, new cracks are developed.

HRD technique is in operation near Valles Caldera, U.S.A., where fractures are made at a depth of 2.76 km and temperature at the location is about 185°C.

Essay # 4. Magma Resources (Molten-Rock-Chamber Systems):

At some places, especially in the vicinity of relatively recent volcanic activity, molten or partially molten rock (i.e. magma) occurs at a moderate depth (less than 5 km). The very high temperature above 650°C and the large volume make magma substantial geothermal resources.

This resource has not been used yet due to the reason that the existing technology does not allow recovery of heat from these resources (Magma technology requires special manufacturing technology).

Essay # 5. Hybrid Geothermal Fossil Systems:

Such a system utilises the relatively low-temperature heat of geothermal resources in the low temperature end of a conventional cycle and the high temperature heat from fossil-fuel combustion in the high temperature end of that cycle.

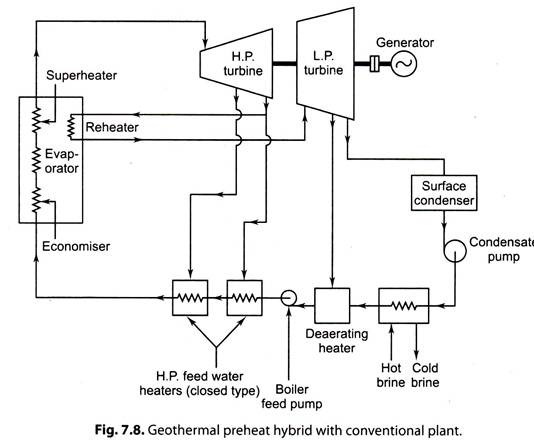

Fig. 7.8 shows the schematic diagram of a geothermal preheat hybrid system, in which low-temperature geothermal energy is used to heat feed water of a conventional fossil fuel system.

In this system geothermal heat heats the feed water throughout the low-temperature steam end prior to an open-type deaerating heater. It is followed by a boiler feed pump and two closed-type feed water heaters with drains cascaded backward. These receive heat from steam bled from H.P. (high pressure) stages of turbine. No steam is bled from L.P. (low pressure) stages because ‘geothermal brine’ fulfills this function.