After reading this essay you will learn about handling and collection of ash and dust generated during the combustion of coal. Also learn about the layout of ash handling and dust collection system.

Essay # 1. Ash Handling:

A huge quantity of ash is produced in central stations, sometimes being as much as 10 to 20% of the total quantity of coal burnt in a day. Hundreds of tonnes of ash may have to be handled every day in large power stations and mechanical devices become indispensable. A station using low grade fuel has to deal with large quantities of ash.

Handling of ash includes:

(i) Its removal from the furnace.

(ii) Loading on the conveyers and delivery to the fill or dump from where it can be disposed off by sale or otherwise.

Handling of ash is a problem because ash coming out of the furnace is too hot, it is dusty and irritating to handle and is accompanied by some poisonous gas.

Ash needs to be quenched before handling due to following reasons:

(i) Quenching reduces corrosion action of the ash.

(ii) It reduces the dust accompanying the ash.

(iii) It reduces temperature of the ash.

(iv) Ash forms clinkers by fusing in large lumps and by quenching clinkers will disintegrate.

Characteristics of Ash Handling:

A good ash handling plant should have the following characteristics:

1. It should have enough capacity to cope with the volume of ash that may be produced in a station.

2. It should be able to handle large clinkers, boiler refuse, soot etc., with little personal attention of the workmen.

3. It should be able to handle hot and wet ash effectively and with good speed.

4. It should be possible to minimise the corrosive or abrasive action of ashes and dust nuisance should not exist.

5. The plant should not cost much.

6. The operation charges should be minimum possible.

7. The operation of the plant should be noiseless as much as possible.

8. The plant should be able to operate effectively under all variable load conditions.

9. In case of addition of units, it should need minimum changes in original layout of plant.

10. The plant should have high rate of handling.

Equipment Used for Ash Handling:

The commonly used equipment for ash handling in large and medium size plants may comprise of:

(i) Bucket elevator

(ii) Bucket conveyor

(iii) Belt conveyor

(iv) Pneumatic conveyor

(v) Hydraulic sluicing equipment

(vi) Trollies or rail cars etc.

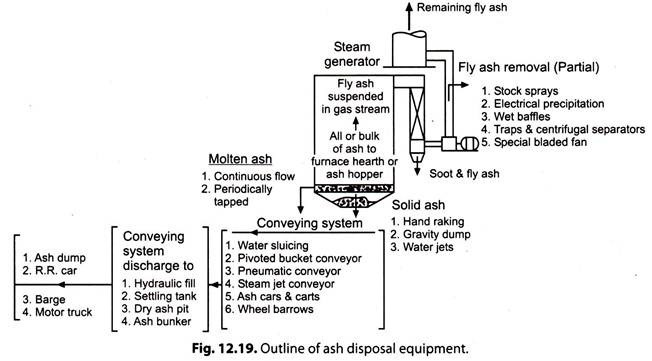

Fig. 12.19. shows the outline of ash disposal equipment.

Uses of Ash Handling:

1. Ash is widely used in the production of cement.

2. Ash is used in the production of concrete, 20 percent fly-ash and 30 percent bottom ash are presently used constructively in U.S.A.

3. Because of their better alkali values, they are used for treating acidic soils. It has been found that if ash is used in limited quantity in soil, it increases the yield of corn, turnip etc.

4. From the ash, the metals such as Al, Fe, Si and titanium can be recovered.

Classification of Ash Handling:

The modern ash-handling systems are mainly classified into four groups:

1. Mechanical handling system

2. Hydraulic system

3. Pneumatic system

4. Steam jet system.

Essay # 2. Dust Collection:

The products of combustion of coal-fed fires contain particles of solid matter floating in suspension. This may be smoke or dust. If smoke, the indication is that combustion conditions are faulty, and the proper remedy is in the design and management of the furnace. If dust, the particles are mainly fine ash particles called “Fly-ash” intermixed with some quantity of carbon-ash material called “cinder”.

Pulverised coal and spreader stoker firing units are the principle types causing difficulty from this source. Other stokers may produce minor quantities of dust but generally not enough to demand special gas cleaning equipment. The two mentioned are troublesome because coal is burned in suspension— in a turbulent furnace atmosphere and every opportunity is offered for the gas to pick up the smaller particles and sweep them along with it.

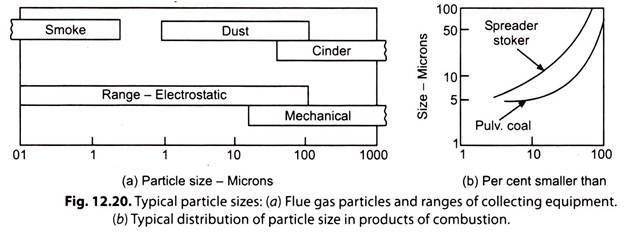

The size of the dust particles is measured in microns. The micron is one millionth of a metre. As an indication of the scale of this measure, the diameter of a human hair is approximately 80 microns. Typical classification of particles by name is given in Fig. 12.20, but the limits shown are, for the most part, arbitrary. A critical characteristic of dust is its “Settling Velocity” in still air. This is proportional to the product of the square of micron size and mass density.

Removal of Smoke:

Smoke is produced due to the incomplete combustion of fuels. Smoke particles are less than 1 micron in size.

The smoke disposal to the atmosphere is not desirable due to the following reasons:

(i) Smoke is produced due to incomplete combustion of coal. This will create a big economic loss due loss of heating value of coal.

(ii) A smoky atmosphere is unhealthy.

(iii) Smoke corrodes the metals, darkens the paints and gives lower standards of cleanliness.

In order to check the nuisance of smoke the coal should be completely burnt in the furnace. The presence of dense smoke indicates poor furnace conditions and a loss in efficiency and capacity of a boiler plant.

Removal of Dust and Dust Collectors:

The removal of dust and cinders from flue gas can usually be effected to the required degree by commercial dust collectors.

The dust collectors may be classified as follows:

1. Mechanical dust collectors:

(i) Wet type (Scrubbers):

(a) Spray type

(b) Packed type

(c) Impingement type.

(ii) Dry type:

(a) Gravitational separators

(b) Cyclone separators.

2. Electrical dust collectors:

(i) Rod type

(ii) Plate type.

Essay # 3. General Layout of Ash Handling and Dust Collection System:

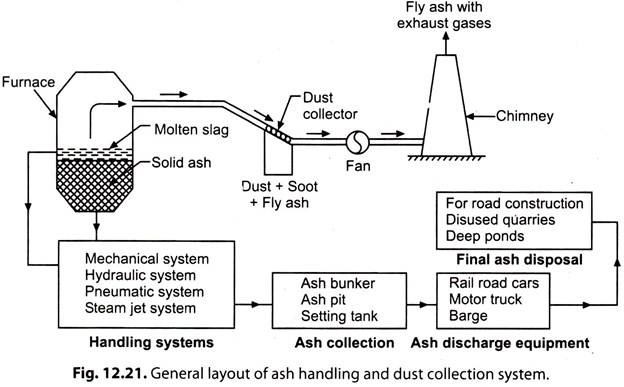

Fig. 12.21 shows the general layout of ash handling and dust collection system which is self-explanatory.