Here is a compilation of essays on ‘Anaerobic Digestion’ for class 9, 10, 11 and 12. Find paragraphs, long and short essays on ‘Anaerobic Digestion’ especially written for school and college students.

Essay on Anaerobic Digestion

Essay Contents:

- Essay on the Meaning of Anaerobic Digestion

- Essay on the Process of Anaerobic Digestion

- Essay on the Stages of Anaerobic Digestion

- Essay on the Configurations of Anaerobic Digestors

- Essay on the Products of Anaerobic Digestion

- Essay on the Applications of Anaerobic Digestion

Essay # 1. Meaning of Anaerobic Digestion:

Anaerobic digestion is a series of processes in which microorganisms break down biodegradable material in the absence of oxygen and is widely used to treat wastewater. As part of an integrated waste management system, anaerobic digestion reduces the emission of landfill gas into the atmosphere. Anaerobic digestion is widely used as a renewable energy source because the process produces a methane and carbon dioxide rich biogas suitable for energy production helping replace fossil fuels. Also, the nutrient rich digestate can be used as fertiliser.

The digestion process begins with bacterial hydrolysis of the input materials in order to break down insoluble organic polymers such as carbohydrates and make them available for other bacteria. Acidogenic bacteria then convert the sugars and amino acids into carbon dioxide, hydrogen, ammonia, and organic acids. Acetogenic bacteria then convert these resulting organic acids into acetic acid, along with additional ammonia, hydrogen, and carbon dioxide. Methanogens, finally are able to convert these products to methane and carbon dioxide.

Previously, the technical expertise required to maintain anaerobic digesters coupled with high capital costs and low process efficiencies had limited the level of its industrial application as a waste treatment technology. Anaerobic digestion facilities have, however, been recognised by the United Nations Development Programme as one of the most useful decentralised sources of energy supply, as they are less capital intensive than large power plants.

Essay # 2. The Process of Anaerobic Digestion:

There are a number of microorganisms that are involved in the process of anaerobic digestion including acetic acid-forming bacteria (acetogens) and methane-forming archaea (methanogens). These organisms feed upon the initial feedstock, which undergoes a number of different processes converting it to intermediate molecules including sugars, hydrogen and acetic acid before finally being converted to biogas.

Different species of bacteria are able to survive at different temperature ranges. Ones living optimally at temperatures between 35-40 °C are called mesophiles or mesophilic bacteria. Some of the bacteria can survive at the hotter and more hostile conditions of 55-60 °C, these are called thermophiles or thermophilic bacteria. Methanogens come from the primitive group of archaea. This family includes species that can grow in the hostile conditions of hydrothermal vents. These species are more resistant to heat and can therefore operate at thermophilic temperatures, a property that is unique to bacterial families.

As with aerobic systems the bacteria in anaerobic systems the growing and reproducing microorganisms within them require a source of elemental oxygen to survive.

In an anaerobic system there is an absence of gaseous oxygen. Gaseous oxygen is prevented from entering the system through physical containment in sealed tanks. Anaerobes access oxygen from sources other than the surrounding air. The oxygen source for these microorganisms can be the organic material itself or alternatively may be supplied by inorganic oxides from within the input material.

When the oxygen source in an anaerobic system is derived from the organic material itself, then the ‘intermediate’ end products are primarily alcohols, aldehydes, and organic acids plus carbon dioxide. In the presence of specialised methanogens, the intermediates are converted to the ‘final’ end products of methane, carbon dioxide with trace levels of hydrogen sulfide. In an anaerobic system the majority of the chemical energy contained within the starting material is released by methanogenic bacteria as methane.

Populations of anaerobic microorganisms typically take a significant period of time to establish themselves to be fully effective. It is therefore common practice to introduce anaerobic microorganisms from materials with existing populations. This process is called ‘seeding’ the digesters and typically takes place with the addition of sewage sludge or cattle slurry.

Essay # 3. Stages of Anaerobic Digestion:

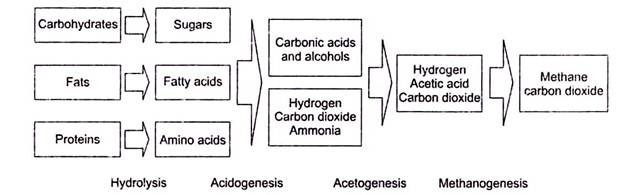

There are four key biological and chemical stages of anaerobic digestion:

1. Hydrolysis

2. Acidogenesis

3. Acetogenesis

4. Methanogenesis

In most cases biomass is made up of large organic polymers. In order for the bacteria in anaerobic digesters to access the energy potential of the material, these chains must first be broken down into their smaller constituent parts. These constituent parts or monomers such as sugars are readily available by other bacteria.

The process of breaking these chains and dissolving the smaller molecules into solution is called hydrolysis. Therefore hydrolysis of these high molecular weight polymeric components is the necessary first step in anaerobic digestion. Through hydrolysis the complex organic molecules are broken down into simple sugars, amino acids, and fatty acids.

Acetate and hydrogen produced in the first stages can be used directly by methanogens. Other molecules such as Volatile Fatty Acids (VFA’s) with a chain length that is greater than acetate must first be catabolised into compounds that can be directly utilised by methanogens.

The biological process of acidogenesis is where there is further breakdown of the remaining components by acidogenic (fermentative) bacteria. Here VFAs are created along with ammonia, carbon dioxide and hydrogen sulfide as well as other by products. The process of acidogenesis is similar to the way that milk sours.

The third stage anaerobic digestion is acetogenesis. Here simple molecules created through the acidogenesis phase are further digested by acetogens to produce largely acetic acid as well as carbon dioxide and hydrogen.

The terminal stage of anaerobic digestion is the biological process of methanogenesis. Here methanogens utilise the intermediate products of the preceding stages and convert them into methane, carbon dioxide and water. It is these components that makes up the majority of the biogas emitted from the system. Methanogenesis is sensitive to both high and low pHs and occurs between pH 6.5 and pH 8. The remaining, non-digestable material which the microbes cannot feed upon, along with any dead bacterial remains constitutes the digestate.

A simplified generic chemical equation for the overall processes outlined above is as follows:

C6H12O6 → 3CO2 + 3CH4

Essay # 4. Configurations of Anaerobic Digestors:

Anaerobic digesters can be designed and engineered to operate using a number of different process configurations:

(i) Batch or continuous

(ii) Temperature- Mesophilic or thermophilic

(iii) Solids content- High solids or low solids

(iv) Complexity- Single stage or multistage.

(i) Batch or continuous:

A batch system is the simplest form of digestion. Biomass is added to the reactor at the start of the process in a batch and is sealed for the duration of the process. Batch reactors suffer from odour issues that can be a severe problem when they are emptied.

Typically biogas production will be formed with a normal distribution pattern over time. The operator can use this fact to determine when they believe the process of digestion of the organic matter has completed. As the batch digestion is simple and requires less equipment and lower levels of design work it is typically a cheaper form of digestion.

In continuous digestion processes organic matter is constantly or added in stages to the reactor. Here the end products are constantly or periodically removed, resulting in constant production of biogas. Examples of this form of anaerobic digestion include, Continuous Stirred-Tank Reactors (CSTRs), Upflow Anaerobic Sludge Blanket (UASB), Expanded Granular Sludge Bed (EGSB) and Internal Circulation reactors (IC).

(ii) Temperature:

There are two conventional operational temperature levels for anaerobic digesters, which are determined by the species of methanogens in the digesters:

i. Mesophilic which takes place optimally around 37°-41 °C or at ambient temperatures between 20°-45 °C where mesophiles are the primary microorganism present.

ii. Thermophilic which takes place optimally around 50°-52° at elevated temperatures up to 70 °C where thermophiles are the primary microorganisms present.

A limit case has been reach in Bolivia, with anaerobic digestion in temperature working conditions less than 10 °C. The anaerobic process is very slow, taking more than three times the mesophilic normal time process.

There are a greater number of species of mesophiles than thermophiles. These bacteria are also more tolerant to changes in environmental conditions than thermophiles. Mesophilic systems are therefore considered to be more stable than thermophilic digestion systems.

Thermophilic digestion systems are considered to be less stable, however the increased temperatures facilitate faster reaction rates and hence faster gas yields. Operation at higher temperatures facilitates greater sterilisation of the end digestate. In countries where legislation, such as the Animal By Products Regulations in the European Union, requires end products to meet certain levels of reduction in the amount of bacteria in the output material, this may be a benefit.

A drawback of operating at thermophilic temperatures is that more heat energy input is required to achieve the correct operational temperatures. This increase in energy may not be out-weighed by the increase in the outputs of biogas from the systems. It is therefore important to consider an energy balance for these systems.

(ii) Solids:

Typically there are two different operational parameters associated with the solids content of the feedstock to the digesters:

(i) High-solids

(ii) Low-solids

Digesters can either be designed to operate in high solids content, with a Total Suspended Solids (TSS) concentration greater than -20%, or a low solids concentration less than -15%.

High-solids digesters process thick slurry that requires more energy input to move and process the feedstock. The thickness of the material may also lead to associated problems with abrasion. High-solids digesters will typically have a lower land requirement due to the lower volumes associated with the moisture.

Low-solids digesters can transport material through the system using standard pumps that require significantly lower energy input. Low-solids digesters require a larger amount of land than high-solids due to the increase volumes associated with the increased liquid-to-feedstock ratio of the digesters. There are benefits associated with operation in a liquid environment as it enables more thorough circulation of materials and contact between the bacteria and their food. This enables the bacteria to more readily access the substances they are feeding off and increases the speed of gas yields.

Number of stages:

Digestion systems can be configured with different levels of complexity:

(i) One-stage or single-stage

(ii) Two-stage or multi-stage.

A single-stage digestion system is one in which all of the biological reactions occur within a single sealed reactor or holding tank. Utilising a single-stage reduces construction costs, however facilitates less control of the reactions occurring within the system. Acidogenic bacteria, through the production of acids, reduce the pH of the tank. Methanogenic bacteria operate in a strictly defined pH range.

Therefore the biological reactions of the different species in a single stage reactor can be in direct competition with each other. Another one-stage reaction system is an anaerobic lagoon. These lagoons are pond like earthen basins used for the treatment and long-term storage of manures. Here the anaerobic reactions are contained within the natural anaerobic sludge contained in the pool.

In a two-stage or multi-stage digestion system different digestion vessels are optimised to bring maximum control over the bacterial communities living within the digesters. Acidogenic bacteria produce organic acids and more quickly grow and reproduce than methanogenic bacteria. Methanogenic bacteria require stable pH and temperature in order to optimise their performance.

Typically hydrolysis, acetogenesis and acidogenesis occur within the first reaction vessel. The organic material is then heated to the required operational temperature (either mesophilic or thermophilic) prior to being pumped into a methanogenic reactor. The initial hydrolysis or acidogenesis tanks prior to the methanogenic reactor can provide a buffer to the rate at which feedstock is added.

Some European countries require a degree of elevated heat treatment in order to kill harmful bacteria in the input waste. In this instance there may be a pasteurisation or sterilisation stage prior to digestion or between the two digestion tanks. It should be noted that it is not possible to completely isolate the different reaction phases and often there is some biogas that is produced in the hydrolysis or acidogenesis tanks.

Residence:

The residence time in a digester varies with the amount and type of feed material, the configuration of the digestion system and whether it be one-stage or two-stage.

In the case of single-stage thermophilic digestion residence times may be in the region of 14 days, which comparatively to mesophilic digestion is relatively fast. The plug-flow nature of some of these systems will mean that the full degradation of the material may not have been realised in this timescale. In this event digestate exiting the system will be darker in colour and will typically have more odour.

In two-stage mesophilic digestion, residence time may vary between 15 and 40 days.

In the case of mesophilic UASB digestion hydraulic residence times can be (1hour-1day) and solid retention times can be up to 90 days. In this manner the UASB system is able to separate solid an hydraulic retention times with the utilisation of a sludge blanket.

Continuous digesters have mechanical or hydraulic devices, depending on the level of solids in the material, to mix the contents enabling the bacteria and the food to be in contact. They also allow excess material to be continuously extracted to maintain a reasonably constant volume within the digestion tanks.

Essay # 5. Products of Anaerobic Digestion:

There are three principal products of anaerobic digestion:

a. Biogas,

b. Digestate and

c. Water.

a. Biogas:

Biogas holder with lightning protection rods and back-up gas flare

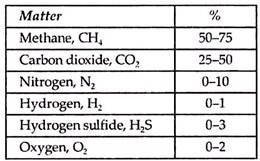

Typical composition of biogas:

Biogas is the ultimate waste product of the bacteria feeding off the input biodegradable feedstock, and is mostly methane and carbon dioxide, with a small amount hydrogen and trace hydrogen sulfide. (As produced, biogas also contains water vapor, with the fractional water vapor volume a function of biogas temperature.)

Most of the biogas is produced during the middle of the digestion, after the bacterial population has grown, and tapers off as the putrescible material is exhausted. The gas is normally stored on top of the digester in an inflatable gas bubble or extracted and stored next to the facility in a gas holder.

The methane in biogas can be burned to produce both heat and electricity, usually with a reciprocating engine or micro-turbine often in a cogeneration arrangement where the electricity and waste heat generated are used to warm the digesters or to heat buildings.

Excess electricity can be sold to suppliers or put into the local grid. Electricity produced by anaerobic digesters is considered to be renewable energy and may attract subsidies. Biogas does not contribute to increasing atmospheric carbon dioxide concentrations because the gas is not released directly into the atmosphere and the carbon dioxide comes from an organic source with a short carbon cycle.

Biogas may require treatment or ‘scrubbing’ to refine it for use as a fuel. Hydrogen sulfide is a toxic product formed from sulfates in the feedstock and is released as a trace component of the biogas. National environmental enforcement agencies such as the U.S. Environmental Protection Agency or the English and Welsh Environment Agency put strict limits on the levels of gasses containing hydrogen sulfide, and if the levels of hydrogen sulfide in the gas are high, gas scrubbing and cleaning equipment (such as amine gas treating) will be needed to process the biogas to within regionally accepted levels. An alternative method to this is by the addition of ferrous chloride FeCl2 to the digestion tanks in order to inhibit hydrogen sulfide production.

Volatile siloxanes can also contaminate the biogas; such compounds are frequently found in household waste and wastewater. In digestion facilities accepting these materials as a component of the feedstock, low molecular weight siloxanes volatilise into biogas. When this gas is combusted in a gas engine, turbine or boiler, siloxanes are converted into silicon dioxide (SiO2) which deposits internally in the machine, increasing wear and tear. Practical and cost-effective technologies to remove siloxanes and other biogas contaminants are available at the present time. In certain applications, in situ treatment can be used to increase the methane purity by reducing the carbon dioxide content.

In countries such as Switzerland, Germany and Sweden the methane in the biogas may be concentrated in order for it to be used as a vehicle transportation fuel or alternatively input directly into the gas mains. In countries where the driver for the utilisation of anaerobic digestion are renewable electricity subsidies, this route of treatment is less likely as energy is required in this processing stage and reduces the overall levels available to sell.

b. Digestate:

Digestate is the solid remnants of the original input material to the digesters that the microbes cannot use. It also consists of the mineralised remains of the dead bacteria from within the digesters. Digestate can come in three forms; fibrous, liquor or a sludge-based combination of the two fractions. In two-stage systems the different forms of digestate come from different digestion tanks. In single stage digestion systems the two fractions will be combined and if desired separated by further processing.

The second by product (acidogenic digestate) is a stable organic material comprised largely of lignin and cellulose, but also of a variety of mineral components in a matrix of dead bacterial cells; some plastic may be present. The material resembles domestic compost and can be used as compost or to make low grade building products such as fibreboard.

The third by product is a liquid (methanogenic digestate) that is rich in nutrients and can be used as a fertiliser dependent on the quality of the material being digested. Levels of Potentially Toxic Elements (PTEs) should be chemically assessed. This will be dependent upon the quality of the original feedstock. In the case of most clean and source-separated biodegradable waste streams the levels of PTEs will be low. In the case of wastes originating from industry the levels of PTEs may be higher and will need to be taken into consideration when determining a suitable end use for the material.

Digestate typically contains elements such as lignin that cannot be broken down by the anaerobic microorganisms. Also the digestate may contain ammonia that is phytotoxic and will hamper the growth of plants if it is used as a soil improving material. For these two reasons maturation or composting stage may be employed after digestion.

Lignin and other materials are available for degradation by aerobic microorganisms such as fungi helping reduce the overall volume of the material for transport. During this maturation the ammonia will be broken down into nitrates, improving the fertility of the material and making it more suitable as a soil improver. Large composting stages are typically used by dry anaerobic digestion technologies.

c. Wastewater:

The final output from anaerobic digestion systems is water. This water originates both from the moisture content of the original waste that was treated but also includes water produced during the microbial reactions in the digestion systems. This water may be released from the dewatering of the digestate or may be implicitly separate from the digestate.

The wastewater exiting the anaerobic digestion facility will typically have elevated levels of Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD), these are measures of the reactivity of the effluent and show an ability to pollute. Some of this material is termed ‘hard COD’ meaning it cannot be accessed by the anaerobic bacteria for conversion into biogas.

If this effluent was put directly into watercourses it would negatively affect them by causing eutrophication. As such further treatment of the wastewater is often required. This treatment will typically be an oxidation stage where air is passed through the water in a sequencing batch reactors or reverse osmosis unit.

Essay # 6. Applications Anaerobic Digestion :

Anaerobic digestion is particularly suited to wet organic material and is commonly used for effluent and sewage treatment. Anaerobic digestion is a simple process that can greatly reduce the amount of organic matter which might otherwise be destined to be landfilled or burnt in an incinerator.

Almost any organic material can be processed with anaerobic digestion. This includes biodegradable waste materials such as waste paper, grass clippings, leftover food, sewage and animal waste. The exception to this is woody wastes that are largely unaffected by digestion as most anaerobes are unable to degrade lignin.

The exception being xylophalgeous anaerobes (lignin consumers), as used in the process for organic breakdown of cellulosic material by a cellulosic ethanol startup company in the U.S. Anaerobic digesters can also be fed with specially grown energy crops such as silage for dedicated biogas production. In Germany and continental Europe these facilities are referred to as biogas plants. A co-digestion or co-fermentation plant is typically an agricultural anaerobic digester that accepts two or more input materials for simultaneous digestion.

In developing countries simple home and farm based anaerobic digestion systems offer the potential for cheap, low-cost energy for cooking and lighting. Anaerobic digestion facilities have been recognized by the United Nations Development Programme as one of the most useful decentralized sources of energy supply.

From 1975, China and India have both had large government backed schemes for adaptation of small biogas plants for use in the house hold for cooking and lighting. Presently, projects for anaerobic digestion in the developing world can gain financial support through the United Nations Clean Development Mechanism if they are able to show they provide reduced carbon emissions.

Pressure from environmentally related legislation on solid waste disposal methods in developed countries has increased the application of anaerobic digestion as a process for reducing waste volumes and generating useful by products. Anaerobic digestion may either be used to process the source separated fraction of municipal waste, or alternatively combined with mechanical sorting systems, to process residual mixed municipal waste. These facilities are called mechanical biological treatment plants.

Utilising anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways:

(i) Replacement of fossil fuels

(ii) Reducing methane emission from landfills

(iii) Displacing industrially-produced chemical fertilizers

(iv) Reducing vehicle movements

(v) Reducing electrical grid transportation losses.

Methane and power produced in anaerobic digestion facilities can be utilized to replace energy derived from fossil fuels, and hence reduce emissions of greenhouse gases. This is due to the fact that the carbon in biodegradable material is part of a carbon cycle. The carbon released into the atmosphere from the combustion of biogas has been removed by plants in order for them to grow in the recent past.

This can have occurred within the last decade, but more typically within the last growing season. If the plants are regrown, taking the carbon out of the atmosphere once more, the system will be carbon neutral. This contrasts to carbon in fossil fuels that has been sequestered in the earth for many millions of years, the combustion of which increases the overall levels of carbon dioxide in the atmosphere.

If the putrescible waste processed in anaerobic digesters was disposed of in a landfill, it would break down naturally and often anaerobically. In this case the gas will eventually escape into the atmosphere. As methane is about twenty times more potent as a greenhouse gas as carbon dioxide this has significant negative environmental effects.

Digestate liquor can be used as a fertilizer supplying vital nutrients to soils. ‘I he solid, fibrous component of digestate can be used as a soil conditioner. The liquor can be used as a substitute for chemical fertilizers which require large amounts of energy to produce and transport. The use of manufactured fertilizers is therefore more carbon intensive than the use of anaerobic digestate fertiliser. This solid digestate can be used to boost the organic content of soils. There are some countries, such as Spain where there are many organically depleted soils, and here the markets for the digestate can be just as important as the biogas.

In countries that collect household waste, the utilization of local anaerobic digestion facilities can help to reduce the amount of waste that requires transportation to centralized landfill sites or incineration facilities. This reduced burden on transportation has and will reduce carbon emissions from the collection vehicles. If localized anaerobic digestion facilities are embedded within an electrical distribution network, they can help reduce the electrical losses that are associated with transporting electricity over a national grid.

In Oakland, California at the East Bay Municipal Utility District’s (EBMUD) Main Wastewater Treatment Plant(MWWTP), food waste is currently co-digested with primary and secondary municipal wastewater solids and other high strength wastes. Compared to municipal wastewater solid digestion, food waste digestion has many benefits.

Anaerobic digestion of food waste pulp from the EBMUD food waste process provides a higher normalized energy benefit, compared to municipal wastewater solids:

(i) 730 to 1,300 kWh per dry ton of food waste applied.

(ii) 560 to 940 kWh per dry ton of municipal wastewater solids applied.

a. Power generation:

Biogas from sewage works is sometimes used to run a gas engine to produce electrical power; some or all of which can be used to run the sewage works. Some waste heat from the engine is then used to heat the digester. It turns out that the waste heat is generally enough to heat the digester to the required temperatures. The power potential from sewage works is limited — in the UK there are about 80 MW total of such generation, with potential to increase to 150 MW, which is insignificant compared to the average power demand in the UK of about 35,000 MW.

The scope for biogas generation from non-sewage waste biological matter — energy crops, food waste, abattoir waste etc., is much higher, estimated to be capable of about 3,000 MW. Farm biogas plants using animal waste and energy crops are expected to contribute to reducing CO2 emissions and strengthen the grid while providing UK farmers with additional revenues.

Gas engine manufacturers include Schmitt Enertec, GE Jenbacher or Caterpillar Inc, and more.

b. Feedstock:

The most important initial issue when considering the application of anaerobic digestion systems is the feedstock to the process. Digesters typically can accept any biodegradable material, however if biogas production is the aim, the level of putrescibility is the key factor in its successful application. The more putrescible the material the higher the gas yields possible from the system.

Substrate composition is a major factor in determining the methane yield and methane production rates from the digestion of biomass. Techniques are available to determine the compositional characteristics of the feedstock, whilst parameters such as solids, elemental and organic analyses are important for digester design and operation.

Anaerobes can breakdown material to varying degrees of success from readily in the case of short chain hydrocarbons such as sugars, to over longer periods of time in the case of cellulose and hemicellulose. Anaerobic microorganisms are unable to break down long chain woody molecules such as lignin.

Anaerobic digesters were originally designed for operation using sewage sludge and manures. Sewage and manure are not however, the material with the most potential for anaerobic digestion as the biodegradable material has already had the energy content taken out by the animal that produced it.

A second consideration related to the feedstock will be moisture content. The wetter the material the more suitable it will be to handling with standard pumps instead of energy intensive concrete pumps and physical means of movement. Also the wetter the material, the more volume and area it takes up relative to the levels of gas that are produced. The moisture content of the target feedstock will also affect what type of system is applied to its treatment.

In order to use a high solids anaerobic digester for dilute feedstocks, bulking agents such as compost should be applied to increase the solid content of the input material. Another key consideration is the carbon: nitrogen ratio of the input material. This ratio is the balance of food a microbe requires in order to grow. The optimal C:N ratio for the ‘food’ a microbe is 20-30:1. Excess N can lead to ammonia inhibition of digestion.

The level of contamination of the feedstock material is a key consideration. If the feedstock to the digesters has significant levels of physical contaminants such as plastic, glass or metals then preprocessing will be required in order for the material to be used. If it is not removed then the digesters can be blocked and will not function efficiently. It is with this logic in mind that mechanical biological treatment plants are designed. The higher the level of pretreatment a feedstock requires, the more processing machinery will be required and hence the project will have higher capital costs.

After sorting or screening to remove any physical contaminants, such as metals and plastics, from the feedstock the material is often shredded, minced and mechanically or hydraulically pulped to increase the surface area available to microbes in the digesters and hence increase the speed of digestion. The feedstock material is then fed into the airtight digester where anaerobic treatment takes place.